Solution

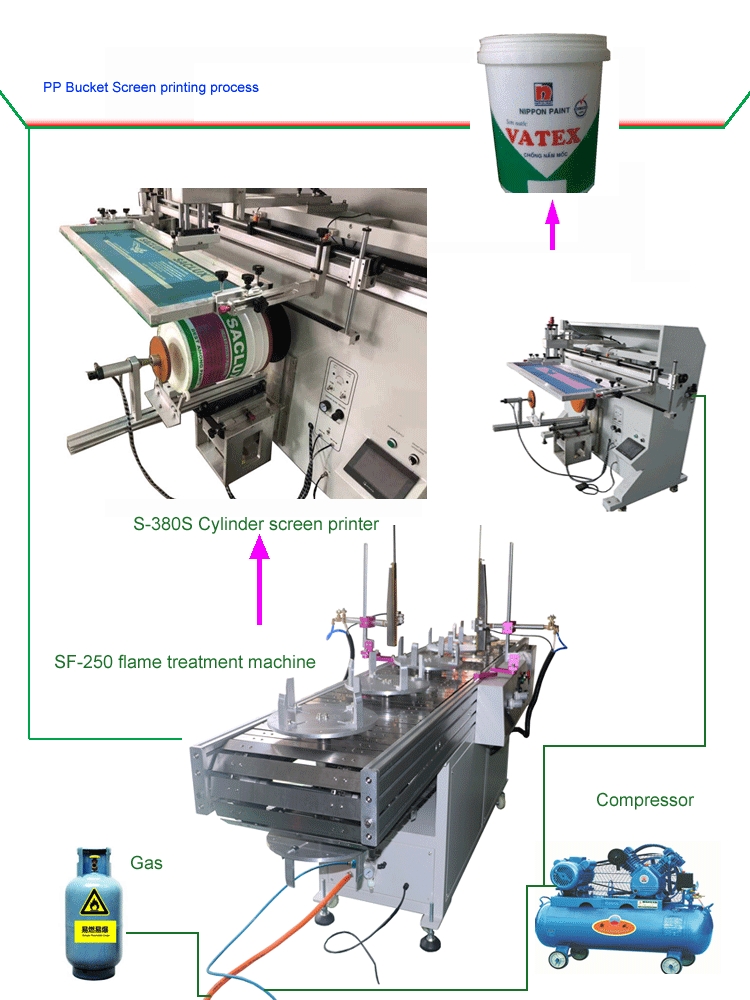

PP PE bucket screen printing solution

Plastic buckets with a diameter of more than 250mm are often used to hold paint, oil and decorative materials. Most of these plastic buckets are made of polypropylene and polyethylene materials. The more common printing method for plastic barrels is silk screen printing. For crafts with colors ranging from one color to two colors, silk screen printing is the most preferred printing method. In order to improve ink adhesion, flame treatment is recommended before silk screen printing. Therefore, SF250 plastic barrel flame treatment machine plus S-380S curved screen printing machine is a mature solution for printing plastic barrels.

In the plastic packaging industry and cosmetic packaging industry, polyethylene and polypropylene materials are widely used due to their excellent processing ability and chemical corrosion resistance, which has also become a problem that the silk screen printing process must face.

The chemical resistance of polyolefin materials is a weak point for printing, which means that it will reduce the adhesion of ink. The current effective method is to use flame treatment, which can pour oxygen atoms on the surface of polyolefin materials 2. Weaken its non-polarity, thereby improving the adhesion of the ink

For the screen printing process, if the ink is selected correctly and the flame surface treatment is used, the adhesion of the ink will be significantly improved, which will increase the attractiveness of the product itself to users.

UV ink is especially commendable in terms of packaging in the cosmetics industry, because when you choose cosmetics, you are likely to be interested in the high gloss of the ink, mainly due to the gloss of the acrylic resin in the UV ink after curing. Now The use of ink in cosmetic packaging has increased to more than 85%.

Another remarkable feature of the ink is that it must be irradiated by UV lamps to dry, so it is basically in a flowing state on the screen, and the situation of blocking the screen will basically not happen. This is the convenience of the operation, so when With the silk screen printing process, a curing machine with a curved surface must be selected. A single flame processor, curved screen printing machine, and UV curing machine constitute a complete solution for UV curved screen printing, but due to the interruption of the process, it is difficult to increase the printing speed, and the constraints of each link also restrict the technical ability of the operator.

In recent years, the fully automatic hollow container bottle screen printing machine has been popular in the market. It integrates many processes such as automatic feeding, flame treatment, curved surface screen printing, UV curing and automatic unloading, etc., with fast speed, stability and few quality constraints. , has gradually seized the market occupied by semi-automatic printing, and has first been popularized in western developed countries and some large cosmetic factories.

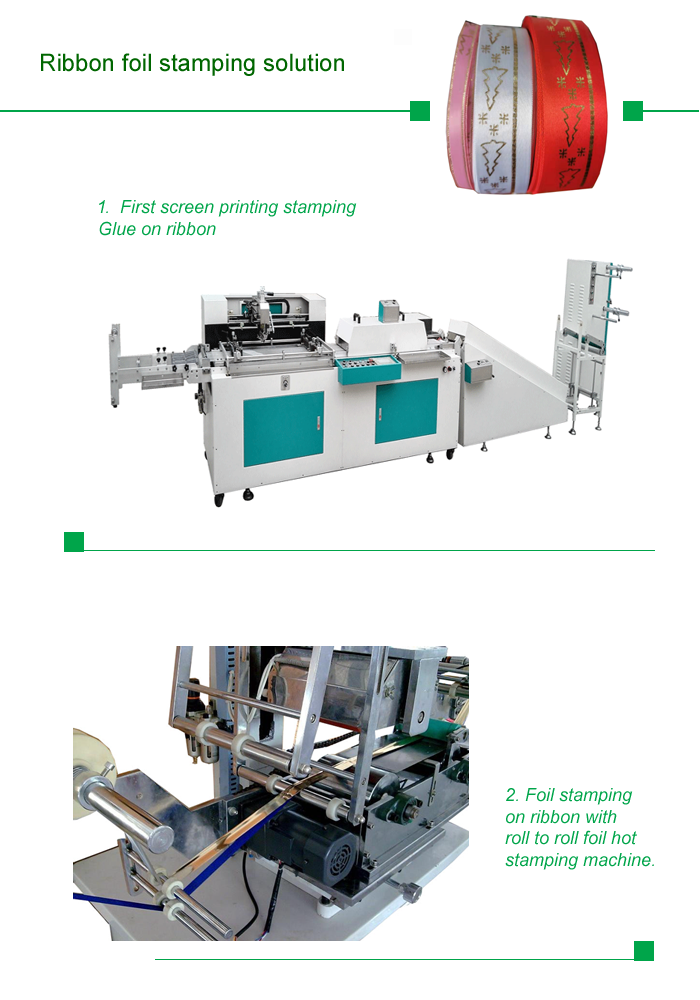

Ribbon indirect foil stamping solution

The more common method of bronzing webbing is to use indirect bronzing process, which is to use a screen printing machine to screen the bronzing pulp on the webbing, and then use the heat transfer machine to tightly press the bronzing paper and the webbing together. The place where there is bronzing pulp will be Transfer the bronzing paper, but the place where there is no bronzing pulp will not transfer the bronzing paper. Because the webbing is in the form of rolls, the screen printing machine should use a roll-to-roll screen printing machine, and the bronzing machine should use a roll-to-roll thermal transfer Printing machine.

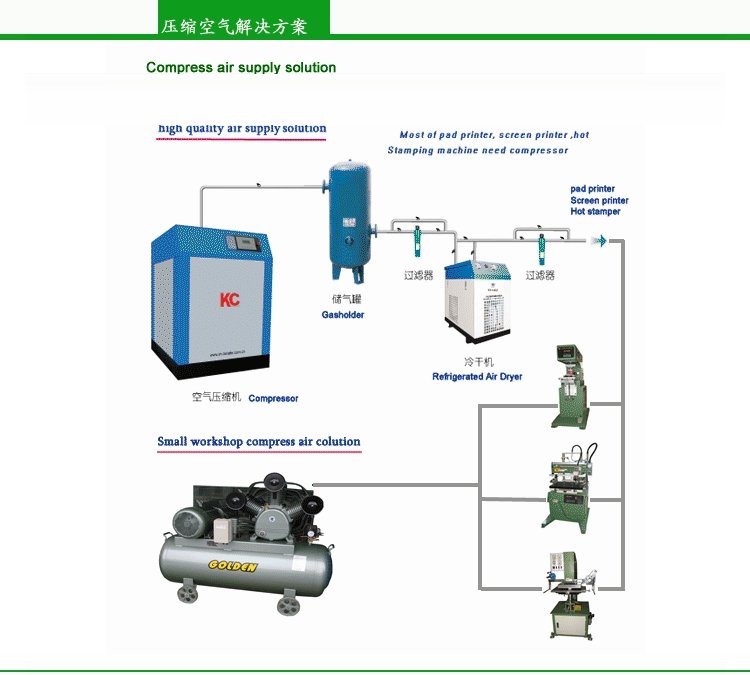

Printing factory compress air supply solution

Pad printing machines, screen printing machines, and hot stamping machines all belong to the category of special printing. Most of them are pneumatically controlled machines. The companies that initially invested in the mainland basically operated under the banner of pneumatic engineering. The so-called pneumatic engineering is to use a microcomputer program to control the solenoid valve. The opening and closing of the solenoid valve is the main feature of the compressed air to control the movement of the cylinder. Therefore, when using pad printers, silk screen printers and hot stamping machines, most factories must provide a source of compressed air or purchase air compressors. Small and medium-sized users can purchase air compressors separately, and large enterprises can purchase high-quality compressed air supply combinations with air compressors as the main body

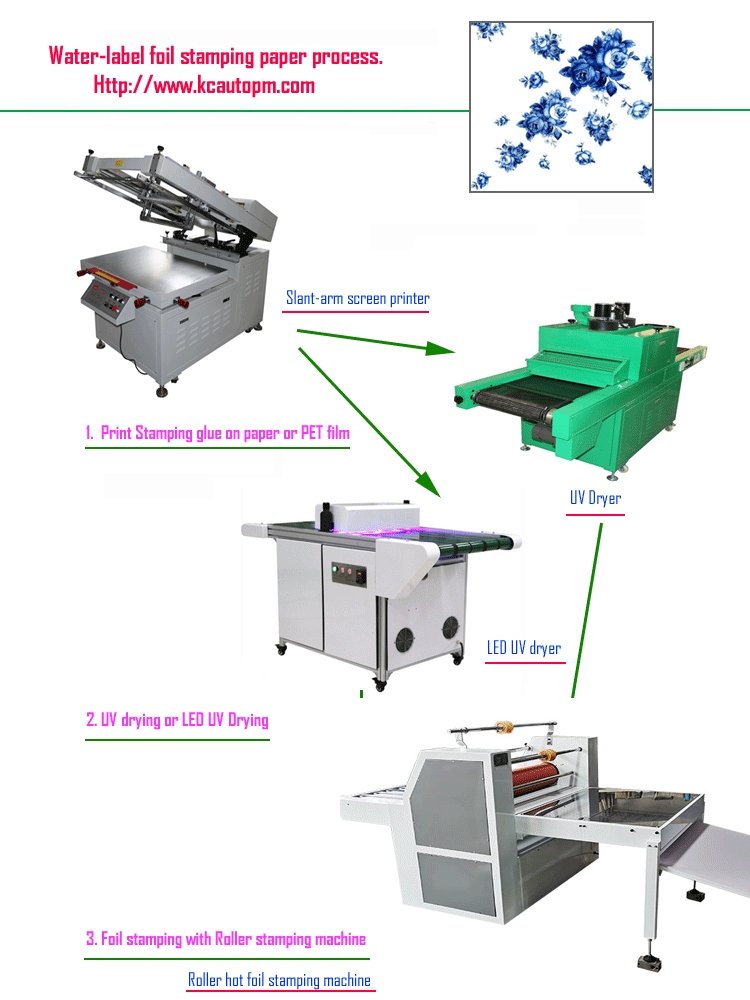

Cold staping water transfer label

It is more difficult to hot stamp text on large-format paper, and the pressure is slightly unbalanced, which will cause many quality problems. For this reason, a so-called cold bronzing process emerged. The cold hot stamping process is to first use a flat screen printer to print solvent-based or UV varnish on the parts that need hot stamping, and then dry it, and then use a roller-type thermal transfer machine to laminate and press the hot stamping paper and paper. Then peel off the hot stamping paper, and the hot stamping paper will remain where the varnish is printed. Because it hardly depends on temperature, it is called cold stamping process, which is widely used in books, magazines, packaging and other decoration processes. The picture shows the application of cold bronzing process on water label transfer paper. In some high-end glass and ceramic wine bottle packaging, water label stickers are commonly used, and the hot stamping process on the water label stickers is the cold bronzing process.

Spot UV screen printing process

The post-processing process of paper is an important method to protect the printed layer and improve the aesthetics of the printed product. The local UV process is the most popular method: it uses a screen printer to print UV varnish on the graphic area that needs to be protected, and then dry it. , This will greatly improve the gloss and expressiveness of the printed graphic area. Compared with the overall varnish protection of the printed matter, it not only saves the cost, but also highlights the theme of the printed matter. The local UV process involves flat screen printing machines and flat UV curing machines. In recent years, with the market’s demand for automation, more and more users have connected semi-automatic screen printing machines and flat UV curing machines with robots to make partial UV The realization of the process is faster and more stable.

Screen printing process for cups

As people's hygiene habits change, more and more fast food restaurants or beverage shops provide consumers with disposable tableware, among which disposable cups are the largest. Disposable cups are thrown away when they are used up, which greatly reduces the spread of germs, so the demand is increasing year after year.

The printing of disposable cups will undoubtedly increase the brand awareness of fast food restaurants or beverage shops. Printing practitioners provide disposable cups while providing brand printing services as the main means to gain market favor.

At present, the printing of disposable cups is mainly flexographic printing, silk screen printing, and pad printing is used for very few. The flexographic printing speed is very fast, suitable for multi-color overprinting, but the machine is expensive, not suitable for small and medium-sized enterprises. Although silk screen printing is slow, it has a low entry barrier, attracting many investors to enter.

Disposable cups are mainly made of paper and plastic. One color can be printed with ordinary curved screen printing machine S-75S S-125S etc. If you need to print two colors or more, you can choose a servo-positioned screen printer. The ideal method is to connect the ordinary screen printer and the servo curved screen printer. The ordinary screen printer prints the first color, and the servo screen printer prints the second and third colors. Some customers will also buy UV curing machines to control the environmental protection properties of disposable cups.

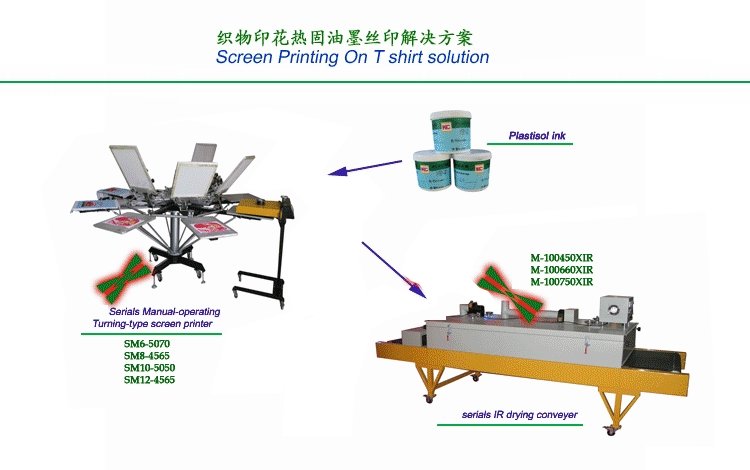

Garment screen printing process

The preferred printing method for textile printing is also silk screen printing, which is suitable for almost all types of inks, whether water-based inks or solvent-based inks. Among fabrics, cotton T-shirts occupy a larger market share, and screen printing is firstly aimed at T-shirts. Such a screen printing scheme involves an octopus screen printing machine. This screen printing machine is suitable for walking on the workbench with platen glue. Both the screen and the table can be rotated for easy color registration and printing. The drying method is infrared drying, because the printing on the fabric is mainly for solvent-based and water-based inks. Water-based inks and solvent-based inks are not easy to dry. When the printing speed is very fast, you may want to consider a longer tunnel drying oven to make the fabric get longer drying time.

Foil stamping solution for glass cups/bottles

The most mature solution for bronzing on the glass material is indirect bronzing, that is, first use a silk screen printer to print a bronzing varnish on the glass surface that needs to be bronzed, then dry it, and then use a thermal transfer machine for transfer. In this way, the area with hot stamping varnish will be transferred to a layer of hot stamping paper, while the area without hot stamping varnish will not have hot stamping paper, thereby completing the distinction between hot stamping and non-hot stamping areas. Glass hot metal is based on the indirect hot stamping process, inspired by the cold hot stamping process in the paper industry. The hot stamping of flat glass products involves flat screen printing machines and flat heat transfer machines, while products such as glass bottles involve curved screen printing machines and curved heat transfer machines.

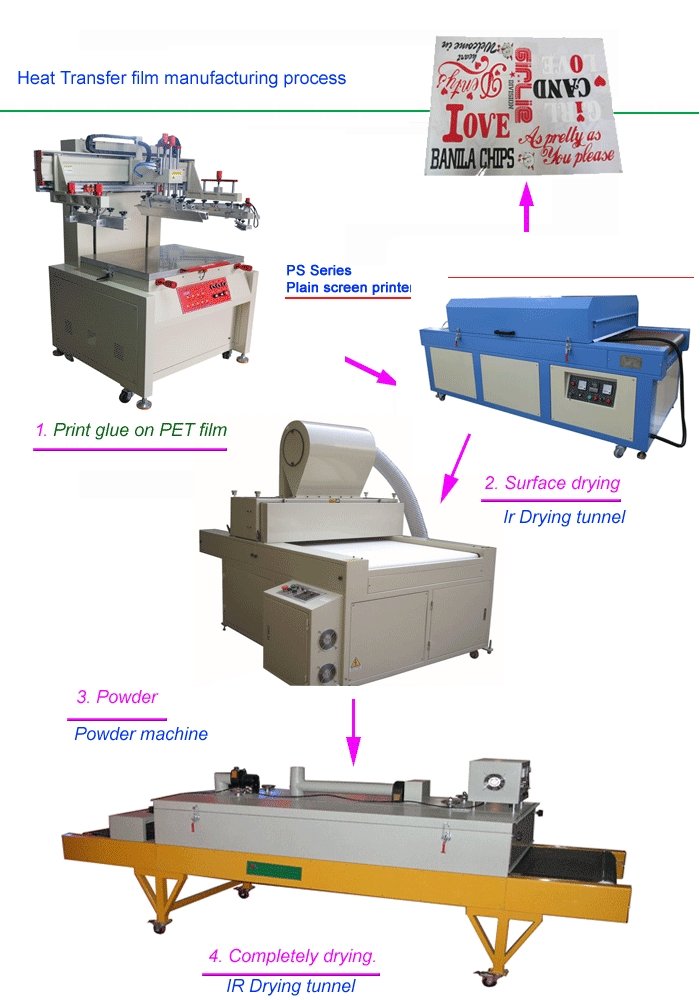

Heat transfer film production process

Heat transfer processing on the fabric is a very important decoration method. First, put the finished heat transfer film and the fabric on the worktable of the heat transfer machine, and heat and press the heat transfer machine for a period of time. The graphics and text on the film will be transferred to the fabric. The process of heat transfer is very simple, but it is not easy to make heat transfer film. It is a more complicated procedure. The screen printing machine plays an important role in the production of heat transfer film. First, select the release PET film to perform the pattern overcolor screen printing. You can choose an oblique arm type suction screen printing machine or a vertical flat screen printing machine. After the silk screen is finished, the surface is dried, and then hot melt powder is sprinkled on the surface of the film, and the drying process is performed again, so that the heat transfer film is completed. The production process of heat transfer film involves flat screen printing machine, tunnel drying oven and dusting machine. Many users connect them into a production line, which greatly improves production efficiency.