News

The structure of automatic screen printing machine

2020-11-30

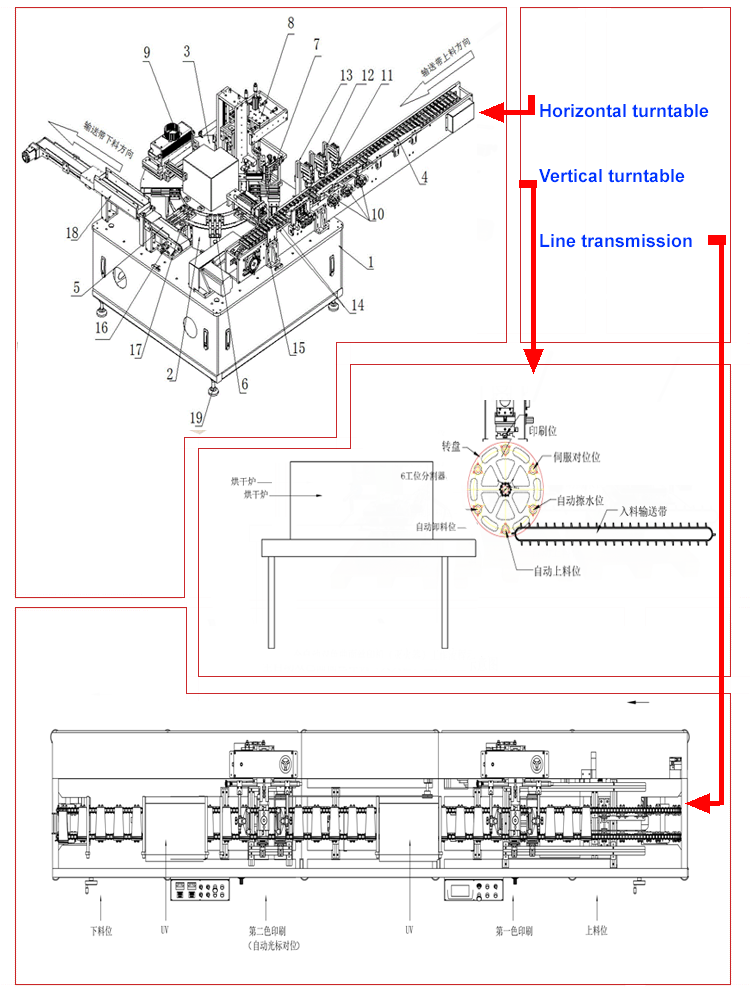

The automatic cylinder screen printing machine mainly has three structural forms, the vertical turntable type screen printing machine, the horizontal turntable type screen printing machine and the linear transmission type screen printing machine. Vertical turntable screen printers are usually used to print single colors. Depending on the shape of the product, a vibrating plate or crawler can be used as the feeding mechanism. Vertical turntable screen printers are more suitable for products with larger bottle mouths, such as cups and hoses. , Jars, some cosmetic jars. The pre-press treatment mainly includes flame treatment and plasma treatment, while the screen printing unit has mechanical positioning and servo positioning. Most automatic screen printers use UV inks, so vertical rotary screen printers are also equipped with UV curing devices, and more and more manufacturing plants use LED UV curing devices.

Vertical turntable screen printers are mainly used to print single colors, but many of these products require multi-color printing. Then, the automatic screen printer with horizontal turntable has obvious advantages. The horizontal turntable screen printer distributes printing on a rotating plane. Pre-processing device, screen printing device, UV curing device, the color can be from two colors to six colors. In order to achieve the accuracy of overprinting, the horizontal rotary screen printer will also use a servo positioning system.

The product transmission route of the linear transmission screen printing machine is roughly a straight line. The basic unit of this screen printing machine is a single-color screen printing machine, which can be connected one by one to achieve multi-color printing, up to 10 colors. The linear transmission screen printing machine has two transmission modes: one is the pendulum transmission type, the other is the chain transmission type. The pendulum transmission type screen printing machine is commonly used for printing containers and bottles with a diameter of more than 25mm, while the chain transmission Screen printing machines are commonly used for printing small diameter products such as penholders, candles, syringes, and reagent bottles. The pendulum transmission type screen printer is usually equipped with a flame treatment unit and a UV curing unit. In addition to the flame treatment unit, the chain transmission type also has an IR drying unit.

The structure of the fully automatic cylindrical screen printing machine is now very popular, and the degree of standardization is high. Most of the cylindrical products involved by the user can basically be printed with them. However, due to the huge differences in the types, shapes, materials, and sizes of cylindrical products, after the user determines the machine selection, it is usually necessary to determine some details of improvement.

Vertical turntable screen printers are mainly used to print single colors, but many of these products require multi-color printing. Then, the automatic screen printer with horizontal turntable has obvious advantages. The horizontal turntable screen printer distributes printing on a rotating plane. Pre-processing device, screen printing device, UV curing device, the color can be from two colors to six colors. In order to achieve the accuracy of overprinting, the horizontal rotary screen printer will also use a servo positioning system.

The product transmission route of the linear transmission screen printing machine is roughly a straight line. The basic unit of this screen printing machine is a single-color screen printing machine, which can be connected one by one to achieve multi-color printing, up to 10 colors. The linear transmission screen printing machine has two transmission modes: one is the pendulum transmission type, the other is the chain transmission type. The pendulum transmission type screen printing machine is commonly used for printing containers and bottles with a diameter of more than 25mm, while the chain transmission Screen printing machines are commonly used for printing small diameter products such as penholders, candles, syringes, and reagent bottles. The pendulum transmission type screen printer is usually equipped with a flame treatment unit and a UV curing unit. In addition to the flame treatment unit, the chain transmission type also has an IR drying unit.

The structure of the fully automatic cylindrical screen printing machine is now very popular, and the degree of standardization is high. Most of the cylindrical products involved by the user can basically be printed with them. However, due to the huge differences in the types, shapes, materials, and sizes of cylindrical products, after the user determines the machine selection, it is usually necessary to determine some details of improvement.