The screen printer is the most widely used type of special printing machinery. It needs to configure the corresponding printing elements for different substrates before printing. For example, making a fixture to hold the product, choosing the screen printing ink that matches the properties of the substrate; making a screen; choosing a suitable squeegee. The structure of the screen printer is different, and the printing elements configured are slightly different.

Rotating plain screen printing machine

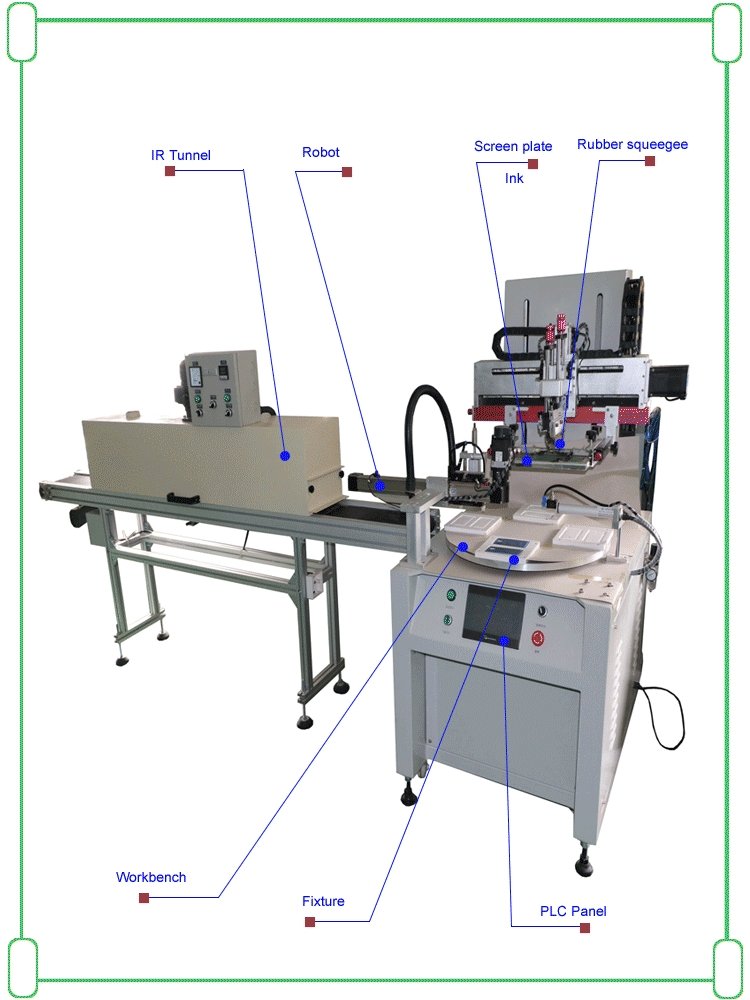

Turntable screen printing machine is an important type of transition from semi-automatic flat screen printing machine to automatic flat screen printing machine. By upgrading the workbench to a structure that can be rotated and alternately conveyed, the degree of automation of the flat screen printing machine has been improved. The turntable table can be set to 4, 6, 8 or more stations ensure the continuous delivery of products and reduce the waste of time during product printing. After the turntable screen printing machine is equipped with a manipulator, the printed product can be grabbed to the IR drying oven or the conveyor belt of the drying oven to realize a relatively automated production line, which is also a trend of today's screen printing machines. The elements of the rotary screen printing machine include:

Screen printing ink, the type of ink is selected according to the material of the product, and the color is selected according to the color required by the design. Whether it is an ink of a famous foreign brand or a domestic brand, as long as it meets the customer's requirements after testing, it can be delivered.

Screen printing jigs: Turntable screen printing machines usually need to make the same number of jigs as the number of workstations, and the uniformity and interchangeability of the jigs are better.

Screen printing screen: The screen printing screen should be made according to the printing pattern provided by the user. You can hand it over to a third party or make it yourself.

Screen printing squeegee: Screen printing squeegee is usually a rubber tool made of polyurethane material with a rectangular or triangular or even more complex cross-sectional shape. It is in close contact with the screen and squeezes the ink onto the product surface through angle and pressure.

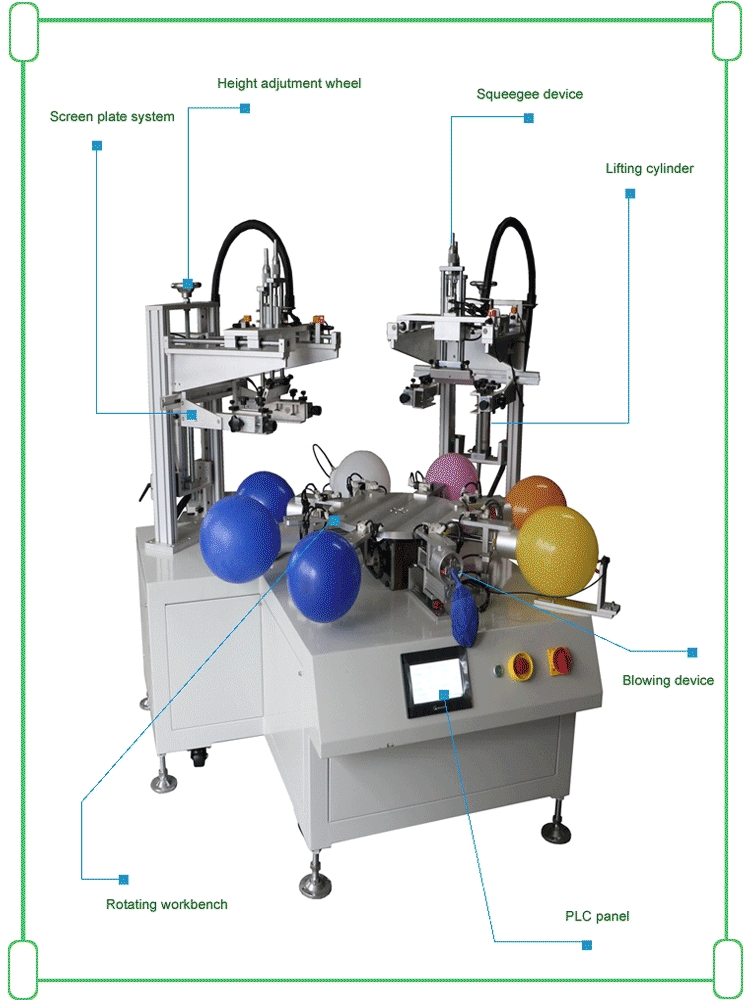

Rotating screen printing machine print on balloon

The balloon screen printing machine belongs to the category of flat screen printing machines, but because the balloon needs to be blown up to a certain size before printing, its softness determines that it will deform under a certain pressure, so the printing accuracy cannot be high, and the accuracy of overprinting Also very low. But the silk screen printing machine is currently the only printing machine that can print on balloons. The fixture of the balloon screen printing machine is a tray, and the balloon is held up during printing, while the screen printing screen and screen printing squeegee are exactly the same as other screen printing machines, but the ink has very distinctive characteristics, such as excellent flexibility and pull Extensibility, its drying speed is also very high. The balloon screen printing machine also has the difference between the standard screen printing machine and the rotary screen printing machine, which mainly determines the difference in the number of fixtures. In addition, when the number of colors exceeds four colors, it is also very common for balloon screen printing machines to adopt the structure of chain assembly line transmission.

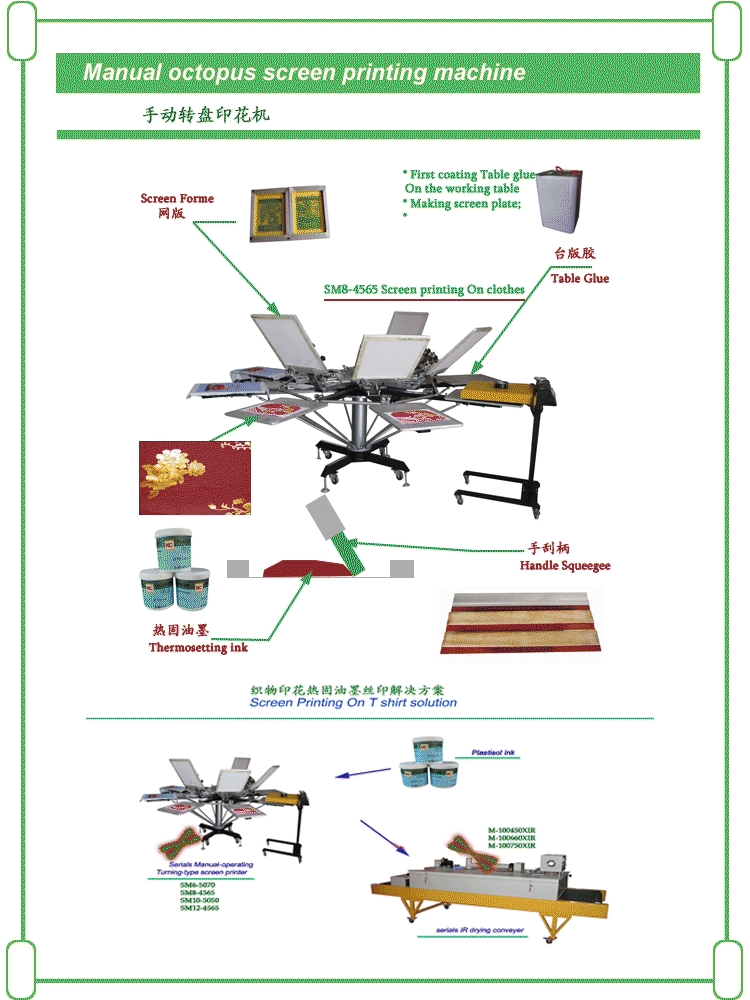

Manual garment screen printing

Textiles are the main source of human clothing, mainly including various pure cotton products and chemical fiber materials. In addition to thermal transfer printing, textiles can also use silk screen printing. The silk screen printing process is different from the silk screen printing process of other printing substrates.

Because textiles touch the human body, they are soft, smooth and breathable. The screen printing machine used is generally a rotary screen printing machine, and the workbench is a platform made of aluminum or wood. In order to ensure the flatness of the textile during printing, The workbench will be coated with a layer of platen glue, which is an adhesive that fixes the textile in a specific position. In multi-color printing, the textile will remain on the platform without any movement.

The ink on textiles is also different from the ink on other plastics. It is generally a variety of solvent-based or water-based glue plus toner. Pyroset inks can also be used. Since these inks cannot damage the human body, the environmental protection requirements are higher. Whether it is mucilage or thermosetting ink, its drying needs to be dried to remove moisture. Therefore, the screen printing machine itself should be used together with a swing oven and a tunnel drying oven.

The silk screen printing process has a very rich expressive force, and the texture of its lines and patterns often dwarfs thermal transfer printing and inkjet printing. However, the silk screen printing process is cumbersome and complicated, and the process line is long, which often discourages investors. cannibalize.

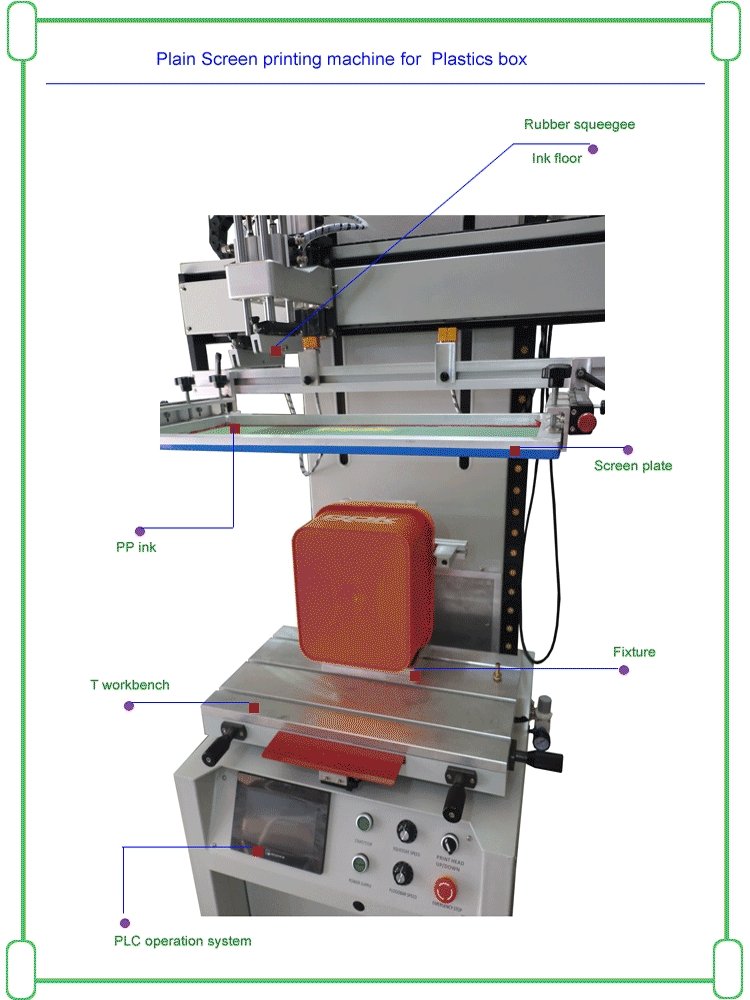

Plain screen printer for Plastics square box

There is a type of product with a huge internal space, such as trash cans, weekly boxes, storage boxes, crates, silk screen on such products, consider making cantilever fixtures, which is to use support mechanisms to support these boxes Stand up for printing, which can reduce the height of the screen printing machine. Cantilever fixtures are widely used in many high-end products. It can avoid the restrictions brought by the internal space of the product. Usually, they require the same graphics and texts to be printed on the corresponding sides, so the cantilever fixtures are set as With the structure of automatic rotation of 90 degrees and 180 degrees, one machine can print two or more positions at a time, which greatly improves production efficiency.

In fact, such a rotating mechanism has mature applications in pad printing machines, bronzing machines, and thermal transfer machines.

In addition to the features on the fixture, the screen printing of the cabinet is the same as the screen printing elements used in other flat products, such as screen, ink, and squeegee.

Shopping bag screen printing machine

It is common to use a screen printer to print shopping bags. For shopping bags with low requirements, you can print directly by placing the bag on the workbench. If the printing requirements for the bag are high, it is recommended to open the bag and make a fixture according to the size of the bag. Although this printing is troublesome, it ensures that the bag has the same thickness during the printing process, and the printing quality is guaranteed. This method can be used for both screen printers and hot stamping machines.

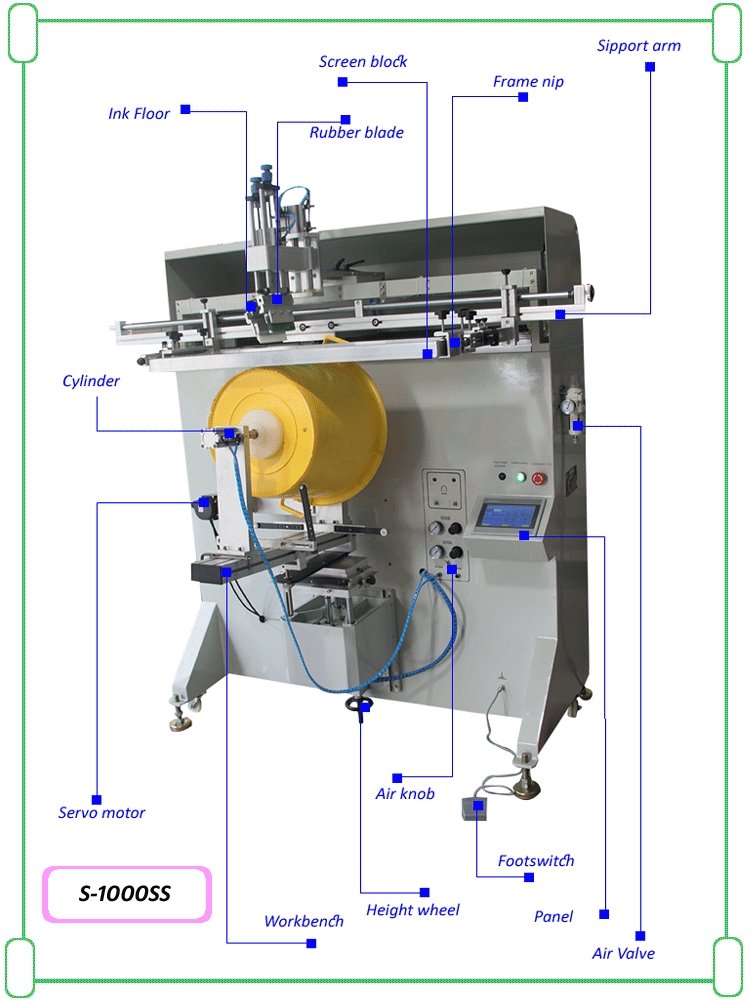

Cylinder screen printer for Barrel

For the printing of cylinders, elliptical cylinders, cones, especially hollow plastic containers, the most preferred choice is the curved surface screen printing machine. The curved surface screen printing machine transfers the left and right movement of the flat screen to the curved surface product through gear transmission or friction transmission. For the printing machinery on the linear contact surface, the continuous rotation of the product, and the part in contact with the surface will continuously receive the ink transfer on the screen to achieve printing.

The significant difference between the curved surface screen printing machine and the flat screen printing machine is that its fixture actually completes the rotation of the product, and the rotation process is in linear contact with the movement of the screen, and no slippage can occur. Therefore, the main elements of the curved screen printing machine are: screen printing screen, screen printing ink, screen printing squeegee, and the squeegee on the curved screen printing machine is usually a squeegee with a triangular cross-section. The screen printing jig has various forms, and its main feature is to ensure the precise and stable rotation of the product.

The curved screen printing machine can print tiny cylinders such as straws and pen refills with a diameter of 1mm, and can also print plastic barrels, oil barrels, and water heater shells with a diameter of more than 500mm. Screens and fixtures will do.

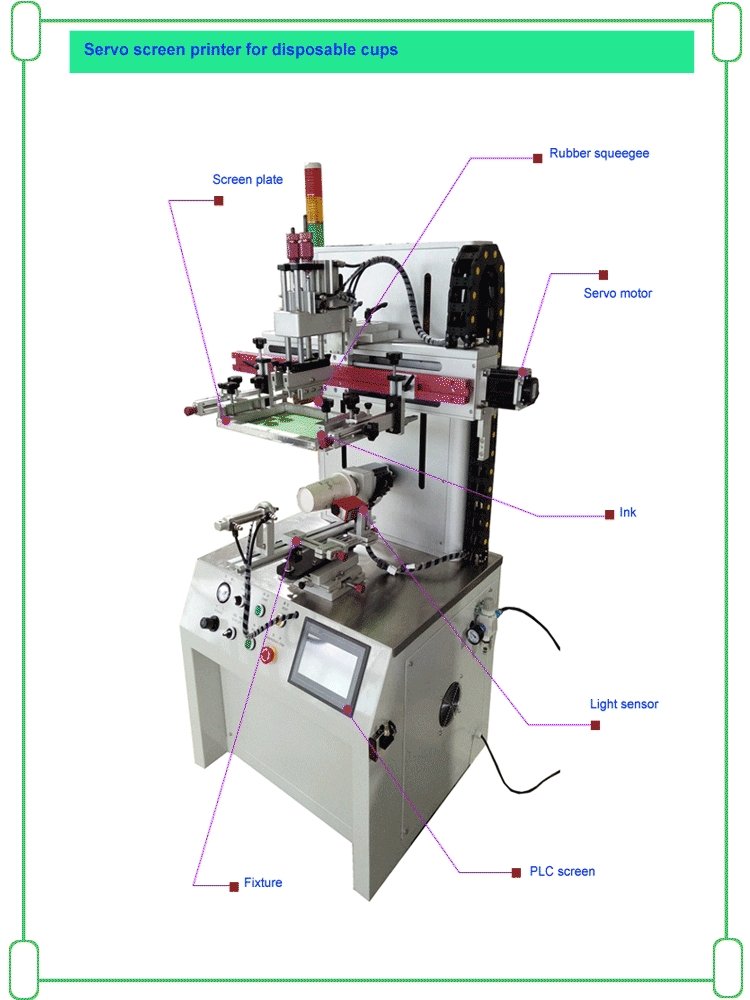

Servo positioning Screen printing for Plastics bottle

Servo-positioned surface screen printing machine is currently the best-selling screen printing machine. It is specially used for color printing of disposable cups without positioning points. It can identify the first color, and then drive the servo motor to rotate to the designated position for the second color. Three-color printing, the printing speed is slow, especially suitable for multi-color silk screen printing of cups with small orders.

The structure of the servo positioning curved screen printing machine is similar to that of the ordinary curved screen printing machine. Except that the servo positioning system is installed on the workbench, the others are basically the same. The printing elements of the servo positioning screen printing machine and the ordinary screen printing machine are also basically the same. It can be said that the screen, squeegee and ink are all common. If there is a difference, the fixture of the servo curved surface screen printing machine requires more precision, and requires no obvious runout tolerance, which will cause inaccurate registration. Although the servo positioning surface screen printing machine can register colors, due to the constraints of various factors, the registration accuracy is not high, generally between 0.10-0.5mm, so it cannot be regarded as a very precise screen printing technology.

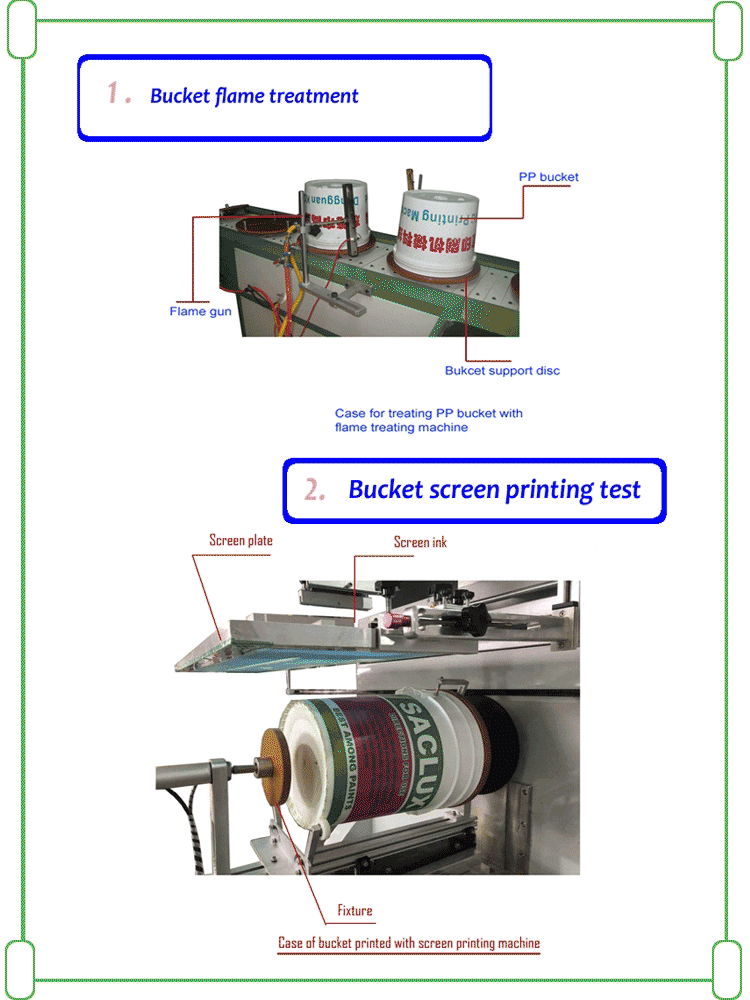

PP plastics bucket screen printing process

In the plastic packaging industry and cosmetic packaging industry, polyethylene and polypropylene materials are widely used due to their excellent processing ability and chemical corrosion resistance, which has also become a problem that the silk screen printing process must face.

The chemical resistance of polyolefin materials is a weak point for printing, which means that it will reduce the adhesion of ink. The current effective method is to use flame treatment, which can pour oxygen atoms on the surface of polyolefin materials 2. Weaken its non-polarity, thereby improving the adhesion of the ink

For the screen printing process, if the ink is selected correctly and the flame surface treatment is used, the adhesion of the ink will be significantly improved, which will increase the attractiveness of the product itself to users.

UV ink is especially commendable in terms of packaging in the cosmetics industry, because when you choose cosmetics, you are likely to be interested in the high gloss of the ink, mainly due to the gloss of the acrylic resin in the UV ink after curing. Now The use of ink in cosmetic packaging has increased to more than 85%.

Another remarkable feature of the ink is that it must be irradiated by UV lamps to dry, so it is basically in a flowing state on the screen, and the situation of blocking the screen will basically not happen. This is the convenience of the operation, so when With the silk screen printing process, a curing machine with a curved surface must be selected. A single flame processor, curved screen printing machine, and UV curing machine constitute a complete solution for UV curved screen printing, but due to the interruption of the process, it is difficult to increase the printing speed, and the constraints of each link also restrict the technical ability of the operator.

In recent years, the fully automatic hollow container bottle screen printing machine has been popular in the market. It integrates many processes such as automatic feeding, flame treatment, curved surface screen printing, UV curing and automatic unloading, etc., with fast speed, stability and few quality constraints. , has gradually seized the market occupied by semi-automatic printing, and has first been popularized in western developed countries and some large cosmetic factories.