Bronzing machine technical parameters determine the scope of its work and work characteristics, understanding bronzing machine technical parameters help to buy and use bronzing machine:

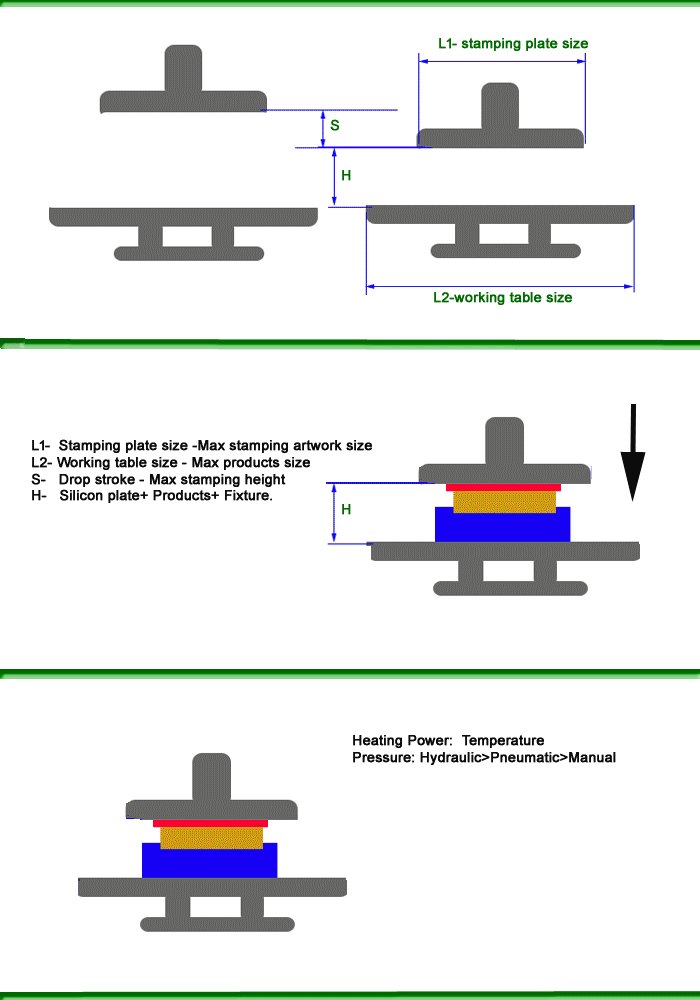

1) table size: table size determines the maximum size of the product, such as HM-TC2129 manual bronzing machine table size: 320 * 400mm, then we recommend using this hot stamping machine stamping Dimensions less than 320 * 400mm products

2) hot plate size: hot plate size determines the size of the largest hot stamping pattern, under normal circumstances, hot stamping machine capable of hot stamping any size smaller than the hot pattern. HM-TC2129 hot plate size 210 * 290mm, it can only be completed less than this size stamping tasks;

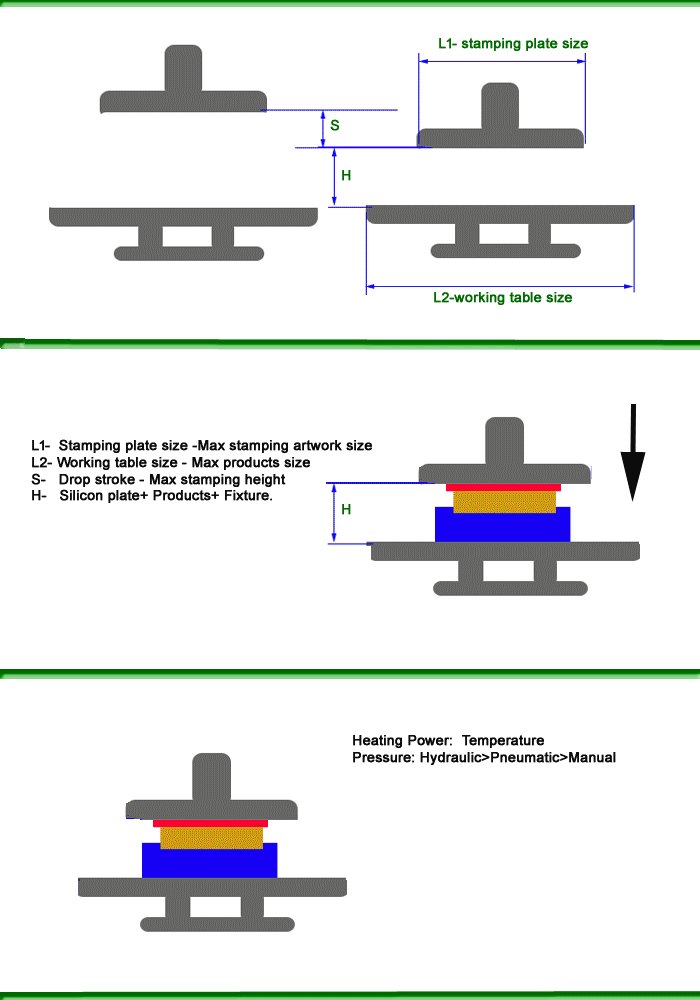

3) Heating power: The heating power is the power of the heating element used to reach this temperature. The greater the heating power, the shorter the time to reach this temperature. The larger the heating plate area, the greater the required power. 250 Degrees below the use of bronzing machine, because the vast majority of products at this temperature can be completed bronzing, if more than this temperature can not be completed bronzing, you need to look at the pressure and gold foil from the top to find countermeasures.

4) Distance : hot plate to the maximum distance of the workbench, there are companies called the opening distance, which determines the maximum height of the product can be hot stamping products, strictly speaking, decided to fixtures, hot stamping products and three The total height of the stack.

Gold foil paper is the most widely used in paper products. Due to the thinness of the paper, the ironing distance is often very small. However, the products in the plastic packaging industry tend to have higher heights and sometimes need to be made. Silicone molds, fixtures, Request will be higher.