The market differentiation of pad printing machines has become more and more obvious in recent years. Some users are sensitive to price requirements, while others are sensitive to quality. Different manufacturers responded quickly to their market segments, and those that supplied pad printing machines to high-end customers continued to refine their products. So what counts as high-quality pad printing? What are the important components that a high-quality pad printing machine usually includes?

A pad printing machine is a simple printing machine that can print on the surface of products with complex shapes. Although most people are only interested in its ability to print, some people are concerned about whether it can achieve more precise printing. For example, what is the repeatability of its multiple printings, and how accurate is the reproduction of details during halftone printing? "Is its ink layer uniform and constant?"

In order to realize these functions, the pad printing machine must be the same as other printing machines, requiring high processing precision of each part of the machine, high precision of mechanical assembly, and complete functions of the machine.

1) Automatic glue head cleaning device

The depth of the pad printing plate determines its ink storage capacity. During the process of dipping the ink and transferring the pad printing pad, some ink will remain on the surface of the pad, and the accumulation will affect the thickness and clarity of the ink layer to a certain extent. The installation of automatic cleaning glue head device can effectively remove the ink on the surface of the glue head and improve the printing quality.

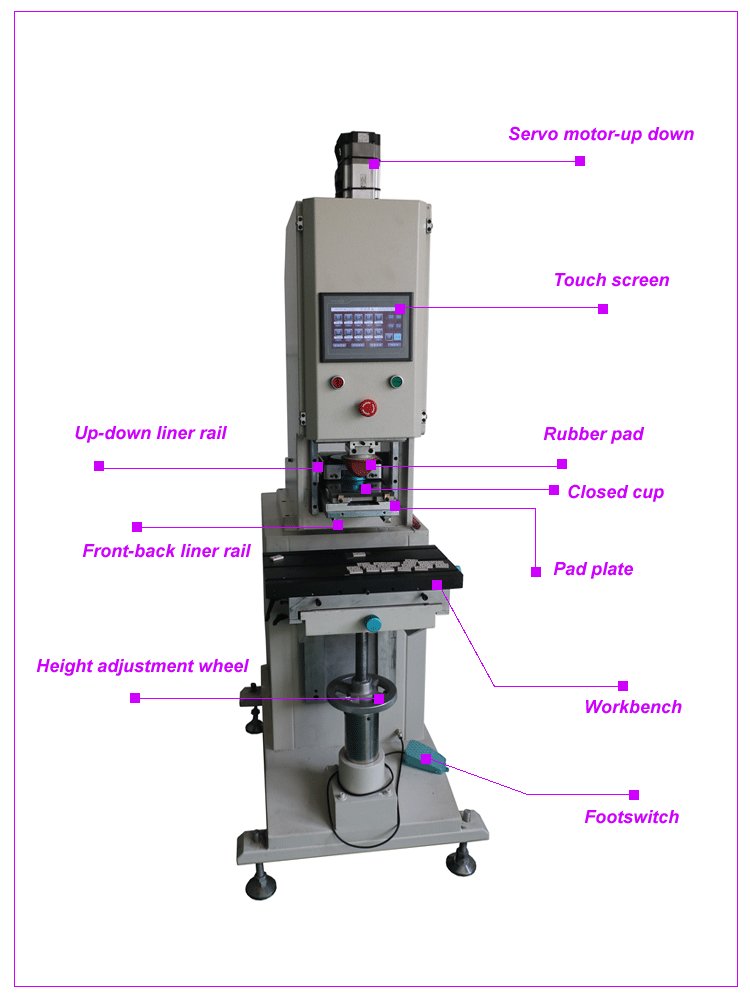

2) Servo drive+PLC

The action of the pad printing machine roughly includes the ink taking of the pad printing head, the movement of the pad printing head, and the printing of the pad printing head. Their moving speed and position have an impact on the printing. Servo drive system and man-machine are used. The program control of the interface can realize the digital control of these actions and avoid misjudgment in experience. The biggest advantage of the human-machine interface is that when printing different products, it can be based on the different properties of the product, such as material, size, and angle. , the printing effect can be set differently.

3) Prepress processing

Pad printing will also involve quite a lot of injection molded PP and PE materials, or some other materials that are not easy to print, you have to consider prepress, and the best prepress is plasma, although plasma is a bit expensive. , but in terms of printing quality stability, plasma has obvious advantages.

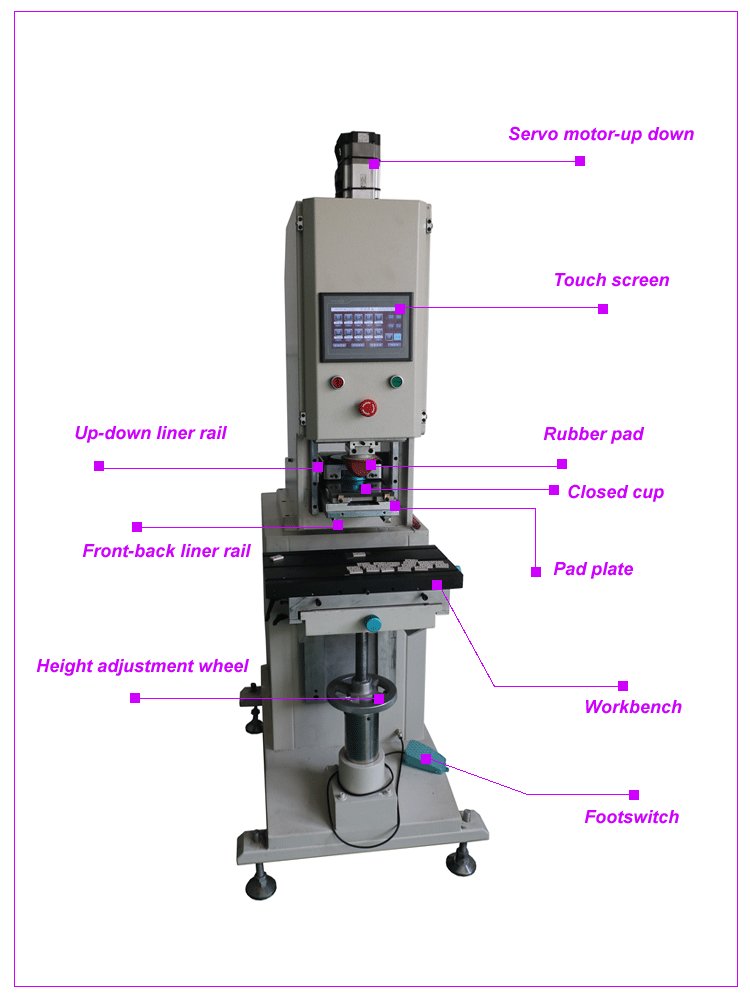

4) Linear guide

The guiding device is an important factor for the mechanical operation to achieve the repeatability. At present, the use of linear guide rails will ensure the repeatability of the pad printing head and the steel plate moving back and forth, which is much more accurate than the traditional guide post.

5) Machining accuracy of mechanical parts

The manufacturing threshold of the pad printing machine is low. It can be manufactured by buying a few lathes and milling machines, and the market is also good. In most cases, the products printed by the pad printing machine do not need too high precision. These pad printing machines no problem. But when you are involved in electronic products, thick film circuits, mobile phone lenses or some military products, it may be required to use CNC to process mechanical parts to achieve higher accuracy, only the accuracy of the parts is high enough, and the accuracy of the assembled machine is also will be higher.