Cups are containers for drinks that people commonly use in their daily lives. There are many kinds and wide range of uses. They can hold beverages, coffee, water and some soups. Whether it is family, social occasions or outdoor sports, Du can see it.

1) Material: The material of the cup covers almost all kinds: paper, plastic, metal, ceramic, glass, wood, rubber.

2) Shape: Most of them are cones with large mouths, there are also some cylinders, and some more complex shapes:

3) Structure, some cups have no lids, some cups have lids, some cups have handles, and some cups have no handles.

4) Some cups will be carried with you, and some cups will be placed at home. Most of the disposable cups, especially those used for leisure drinks, should be thrown away after they are used up to avoid repeated use.

The printing of cups involves almost all printing methods, offset printing, flexographic printing, hot stamping, heat transfer, silk screen printing, pad printing. Screen printing is the most widely used, especially for those cups with handles, which cannot be replaced by other printing methods. As far as screen printing is concerned, semi-automatic screen printing and full-automatic screen printing are all good methods. The screen printing of disposable plastic cups or paper cups that are currently popular in the market, due to the huge amount of use, has begun to use automatic screen printing machines more and more widely. .

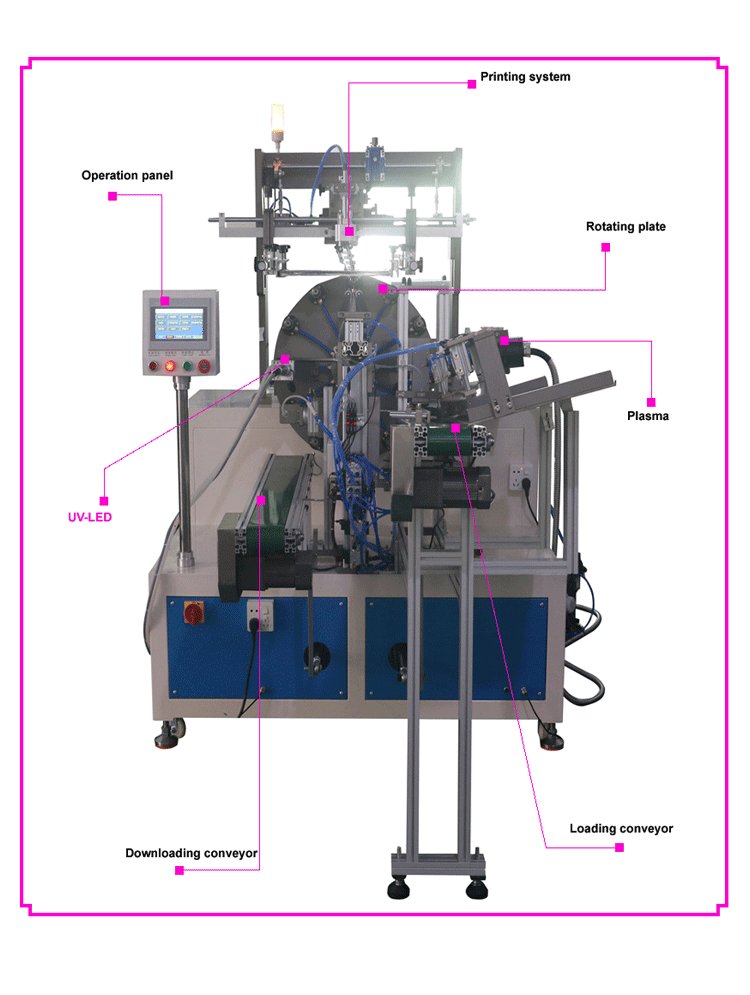

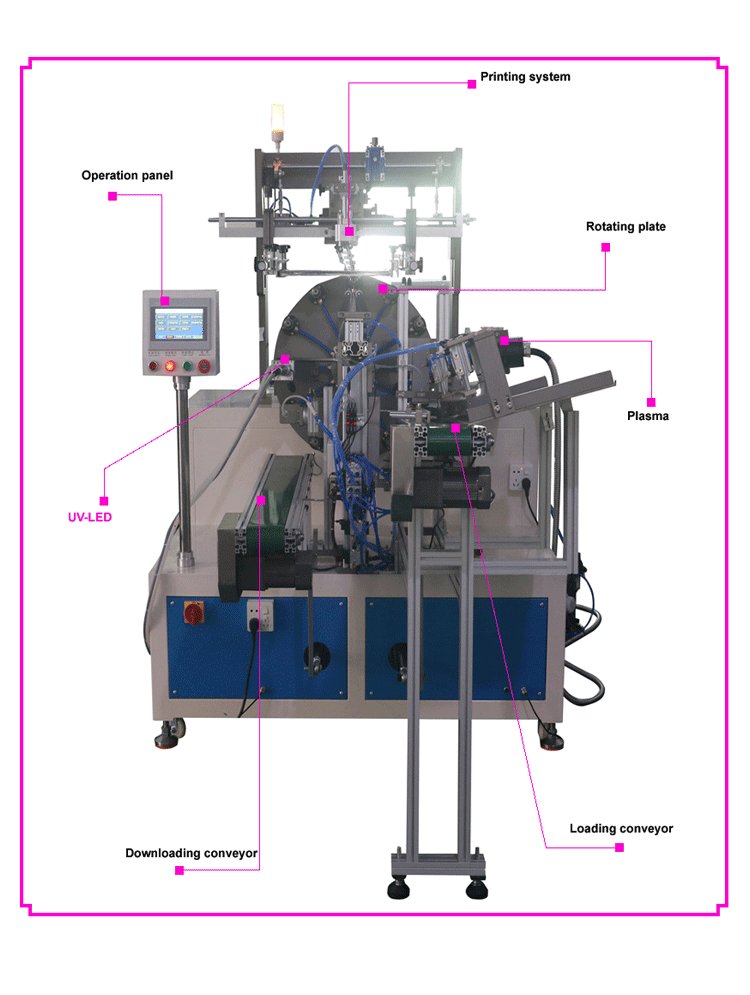

Fully automatic screen printing machine specially designed for disposable cups such as milk tea cups, coffee cups, beverage cups, etc.

The width of the integrated synchronous feeding and feeding device of the whole machine can be adjusted flexibly, which is convenient to adjust according to the size of the cup; the speed can be adjusted steplessly to match the transportation speed with the printing speed;

Automatic manipulator push feeding;

Online flame treatment device or plasma treatment can improve the surface tension of PE material and increase the adhesion of ink;

Stable vertical turntable transmission system, stable operation and high precision;

Automatic screen printing device, the fixture can be changed according to the size of the cup; electronic sensors are installed in the printing area to realize the function of no part without printing; photoelectric switch tracking system can be installed to realize color printing.

High-performance UVLED drying device, instant drying of ink; energy saving, safe and environmentally friendly.

The whole machine realizes mechanical transmission and touch screen operation, which can easily realize man-machine dialogue and make the operation more handy;

The main parts are processed by CNC, the high-quality processing accuracy ensures the stability of high-speed operation, and the printing speed is up to 2000pcs/h;

The electrical components and control system of the whole machine use German and Japanese components to ensure stable printing quality.