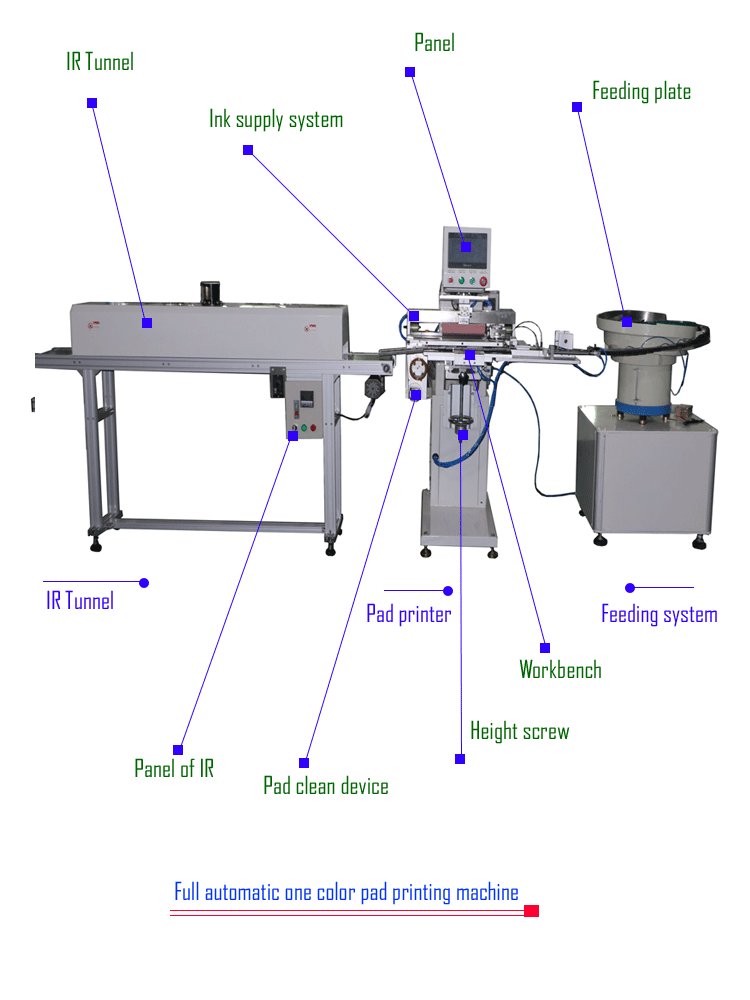

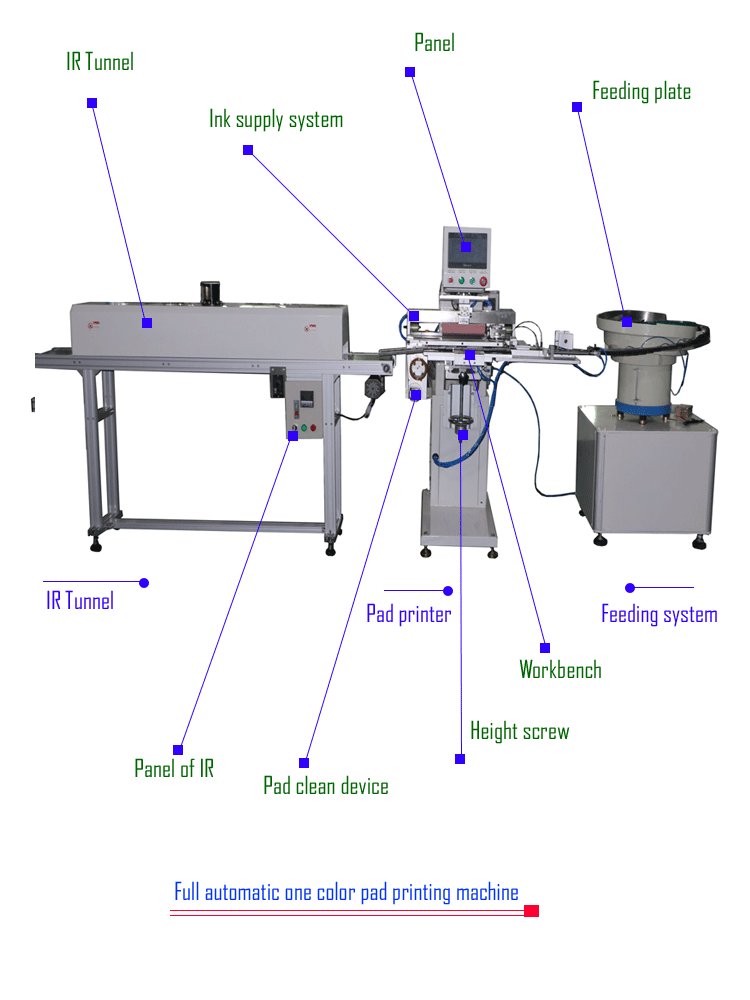

The semi-automatic pad printing machine is slow, the workers are troublesome, and it is difficult to complete the printing tasks of large-volume orders. Now more and more customers are considering customizing the automated pad printing machine. The automatic pad printing machine is the pad printing machine that can complete the integration from transmission, pre-press processing, positioning, printing and drying.

The custom automatic printing machine mainly considers the following aspects

A

1) Feeding method. Is it a vibrating disk or a crawler? The price of the vibration plate is relatively low, and most products can use the vibration plate to feed. However, the vibrating plate is easy to jam, and the noise is loud. For products with relatively regular appearance, the crawler is given priority. The crawler has less noise and is more stable.

2) Pre-press processing. Under normal circumstances, ABS can not use pre-press processing, other plastics, especially polyolefin plastics can consider plasma, flame, PP oxidant wipe, high-frequency processing. PP oxidant treatment may change the surface characteristics of plastics. It is a chemical treatment. Other methods are physical treatment methods. At present, flame treatment and plasma treatment are often used.

3) Positioning. Positioning is very important. It determines the printing position of the product. We usually require a high degree of consistency between the printing position and the shape of the product. This consistency is achieved through the precise positioning of the product. Orientation of direction. Before and after, positioning from left to right is relatively easy, and positioning from top to bottom is not too difficult, just add a depressing mechanism. The positioning in the circumferential direction is relatively difficult. First, it is realized in the feeding mechanism, and secondly, a rotary servo device can also be installed.

4) Printing. The pad printing process is now very popular. According to different customer requirements, it is determined to use different configurations. European and American countries may prefer to use the ink cup ink supply system, while South America, Asia, and Africa countries will consider the oil pan system; It is more popular to use the touch screen to operate the machine. It can easily set the parameters; in order to further improve the printing quality, the machine can also be installed with an automatic head cleaning device, so that the clarity of the imprint will ensure the continuity of printing Will be supported; most of the printing operations adopt pneumatic control. If a servo system is used, the accuracy of the machine will be further improved.

5) Dry. The printing of the finished product believes that the ink must be completely dried, and the most common use of solvent-based inks for pad printing is to install an infrared drying device at the rear of the pad printer to greatly increase the speed of product delivery.

For those who have purchased semi-automatic pad printers, future considerations are likely to bypass automatic pad printers, but automatic pad printers have limitations, that is, automated pad printers can often only print for specific products Once the appearance of the product has changed significantly, the pad printer will either not be able to print or it will require very large changes. Therefore, when you have a large variety of products and the quantity is not very large, you still have to suspend the customization of the automatic printing machine.