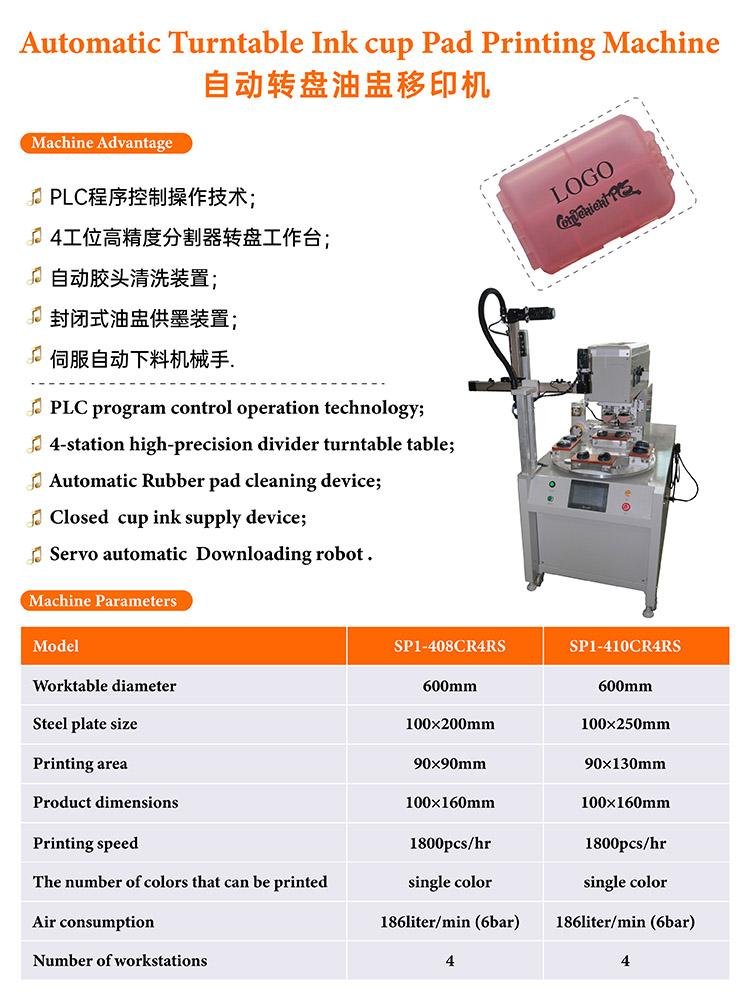

Model No.︰SP1-410CR4RS

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 11688 / pic

Minimum Order︰1 pic

1. Equipment Overview

• The turntable type oil cup double-head pad printer with robot unloading is a highly automated printing equipment, which integrates multiple functions such as turntable structure, double-head printing and robot unloading. It is often used for pad printing operations on the surface of various products to achieve accurate printing of patterns, texts, etc.

2. Working principle and structural characteristics

• Turntable structure: The core of the equipment is the turntable, which is like a rotating workbench with multiple workstations on it. The product to be printed is placed on the workstation of the turntable. The turntable rotates at a constant speed according to the set program, and transports the product to different work areas in turn, such as the loading area, printing area, drying area (if necessary), etc., to ensure that the entire printing process is carried out in an orderly and efficient manner.

• Oil cup design: The oil cup is a key component for storing and supplying ink. It can accurately control the amount and flow of ink, so that the ink is evenly distributed at the position where the pad head needs to dip. Compared with the traditional ink supply method, the oil cup can reduce the volatilization and waste of ink, and can better ensure the consistency of printing quality.

• Double-head printing: equipped with two pad heads, these two pad heads can print the product at the same time, or they can print different colors or different patterns one after another as needed. The double-head design can effectively improve the printing efficiency, especially for printing tasks that require multiple color combinations or complex pattern combinations.

• Robot unloading: After printing is completed, the robot plays a role. It can accurately grab the printed product and remove it from the turntable and place it in the designated unloading area, such as a collection box or a conveyor belt. The entire unloading process is fast, accurate and stable, without manual operation, which further improves the degree of production automation.

3. Advantages

• High-precision printing: The turntable has high rotation accuracy and accurate station positioning. In addition, the oil cup has fine control over the ink and the good performance of the pad printing head, which makes the position of the printed pattern accurate, the lines clear, and the colors uniform and full, which can meet the needs of products with high printing quality requirements, such as electronic product shells, high-end gifts, etc.

• Efficient production: Double-head printing plus the turntable-type continuous workflow and the rapid cooperation of the robot unloading greatly improve the overall production efficiency. Compared with single-head or non-automated pad printing equipment, more products can be printed per unit time, effectively shortening the production cycle, which is suitable for mass production scenarios.

• Save ink and cost: The reasonable design of the oil cup reduces ink waste and reduces the cost of ink use. At the same time, the automated operation mode reduces labor input, reduces labor costs, and reduces the errors and defective rates that may be caused by manual operation, saving production costs in many ways.

• Wide range of applications: Products of different shapes, sizes and materials can be printed. Whether it is a flat, curved or irregular object, as long as it can be placed on the turntable station, it can basically be pad printed. It has strong versatility and is widely used in many industries such as plastic products, hardware products, and glass products.

4. Application areas

• Electronic and electrical industry: used to print brand logos, function button icons, decorative patterns, etc. on mobile phone shells, tablet computer back covers, remote controls and other products to enhance the appearance recognition and aesthetics of the products.

• Plastic products industry: Surface printing of plastic toys, plastic daily necessities, plastic packaging boxes, etc. can add fun to the products, brand promotion elements, etc.

• Hardware products industry: Pad printing of metal crafts, metal accessories, hardware tools, etc., plays the role of identification and decoration, and increases the added value of products.

• Glass products industry: For example, surface printing of glass cups, glass vases, etc., makes the products more personalized and artistic.

|

Robot pad printer with rotating table//Structure |

||||

|

Working table |

4 stations High accurate working table |

|||

|

Ink supply system |

Closed cup ink supply system |

|||

|

Plate type |

10mm Thick steel plate. |

|||

|

Pad dropping control |

Simple-cylinder , Continue pressing |

|||

|

Ink drying |

Heat air |

|||

|

Robot pad printer with rotating table // Usage and Characters |

||||

|

Guide |

|

|||

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|||

|

Robot pad printer with rotating table//Parameter |

||||

|

Technical parameters |

|

|||

|

Works supply |

|

|||

|

Package list |

|

|||

|

H.S.Code |

8443198000 |

|||

|

Certicate |

CE |

|||

|

Robot pad printer with rotating table //Advantage |

||||

|

Function |

|

|||

Application︰ The pad printing machine of the rotary table type is the best-selling pad printing machine on the market at present. It replaces the traditional pneumatically controlled pad printing machine with a circular rotary table controlled by a precision divider, and the rotary table can have 4-6-8-10. Station, transmission accuracy and repeat accuracy have been further improved. As a requirement of automation, turntable pad printing machines can be equipped with automatic feeding manipulators and unloading manipulators to reduce the operator's work intensity. The pad printing machine is also equipped with an automatic cleaning rubber head device to ensure the printing quality. Therefore, the turntable type pad printing machine is an important structural form of the transition from the semi-automatic pad printing machine to the automatic pad printing machine, and is very popular among customers.

Base structure︰

A rotary pad printer usually consists of the following parts:

1) Workbench: The workbench generally consists of 4-6-8-10 printing stations with an even number of positions. The entire rotary table rotates around the central axis. Each time a station is rotated, a pad print is performed. To improve efficiency, more than two products can be printed at a time. The workbench is generally controlled by a divider.

2) Operation panel. The rotary pad printer is more complex than the semi-automatic pad printer. There will be a PLC for action control and data setting. The printing requirements of different products have been achieved.

3) Pad cleaning device: In order to improve the printing quality, the rotary pad printer will be equipped with an automatic pad cleaning device. The ink remaining on the surface of the pad will be automatically removed.

4) Ink supply system: The ink supply system of the rotary pad printer can be an ink tray structure or an ink cup structure. The ink cup structure is more environmentally friendly.

5) Printing system: The printing system can be controlled pneumatically or by a servo motor. The servo motor control will greatly improve the stability and precision of the pad printer.

6) Unloading system: Automatically remove the product from the workbench, which is also one of the basic configurations of the turntable pad printer. The manipulator is designed according to the appearance characteristics of the product and can quickly and accurately remove the product.

7) Prepress treatment: Some products require dust removal, static electricity removal, and flame treatment. Prepress devices with different functions can be installed according to specific conditions.