Model No.︰ST-3050PV

Brand Name︰KC

Country of Origin︰China

Unit Price︰US $ 1617 / pic

Minimum Order︰1 pic

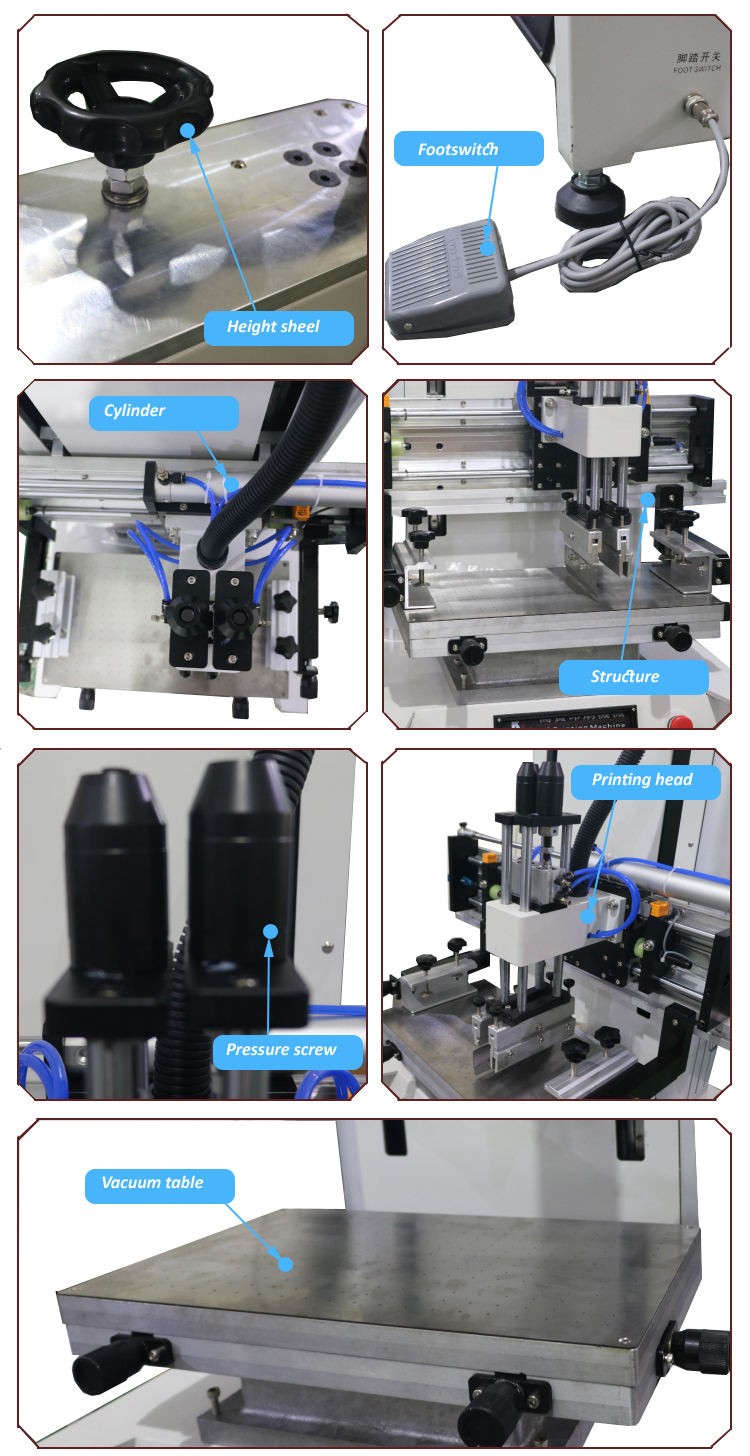

The reduced version of the desktop flat screen printing machine is designed to meet the needs of users in the field of screen printing processing with small investment in the market. It has all the functions of the flat screen printing machine, but the price is very low, and it can print almost all flat products.

It has no chassis and can be operated on the table. It uses pneumatic control and requires an additional purchase of an air compressor; it can also be installed with a suction table and a T-slot table. The suction table is used for printing paper and film, T The groove table is suitable for printing three-dimensional injection molding products.

In terms of precision, its printing area is small, and its precision is completely suitable for most products, and it is also considered to use linear guide rails to control the screen up and down, and it can basically meet the requirements for color registration.

Advantages

• Convenient operation: The computer operation panel makes parameter setting intuitive and simple. Operators can easily set the parameters of the up and down movement of the screen and the left and right movement of the scraper, such as speed, stroke, pressure, etc., without complex training.

• Space saving: The compact design makes it occupy a small area and is suitable for work environments with limited space, such as small studios or shops.

• Cost-effective: The overall performance is good and the price is relatively low, which can meet basic printing needs without bringing excessive costs to users.

• Flexible and efficient: The pneumatically controlled up and down movement of the screen and the left and right movement of the scraper are responsive and precise, which can improve printing efficiency and quality.

Structural composition

• Computer operation panel: As the control center, it integrates the control circuit and operation interface software to achieve precise control of each action of the screen printing machine. Operators can adjust parameters, set programs and monitor operating status here.

• Pneumatic system: includes air source (such as air compressor), pneumatic control valve, cylinder and other components. The pneumatic control valve controls the extension and contraction of the cylinder to achieve the up and down movement of the screen and the left and right movement of the scraper.

• Workbench: It is a platform for placing the substrate, usually with a flat and smooth surface, and some are equipped with adsorption devices to prevent the substrate from moving during the printing process.

• Screen and scraper: The screen is used to carry the printing pattern, with a solid frame and a tight screen; the scraper is generally made of materials such as rubber or polyurethane, with good wear resistance and elasticity to ensure that the ink is evenly scraped across the screen.

• Body: It is constructed of metal materials, providing support and installation foundation for each component, ensuring the stability of the machine, and its compact design makes the whole machine compact.

|

ST-3050PV Flat screen printing machine with vacuum table //Structure |

||

|

Working table |

Vacuum working table, Size: 300*500mm |

|

|

Actions |

Up-down of screen plate |

|

|

To be printed |

|

|

|

Squeegee stroke |

Adjust the Limited switch |

|

|

Squeegee and screen plate control |

High precision Liner guide rail |

|

|

ST-3050V Flat screen printing Machine with vacuum table//Parameters |

||

|

Technical parameters |

|

|

|

Works supply |

|

|

|

Ship parameters |

|

|

|

||

|

H.S.CODE |

8443192190 |

|

|

Certificate |

CE |

|

|

ST-3050PV Flat screen printing Machine with vacuum table //Advantage |

||

|

Function |

|

|

Application︰

The desktop screen printer is equivalent to the vertical screen printer, which can be placed in different places for operation. It has a small footprint and a relatively low price. It is especially suitable for printing small-size products. Therefore, it is widely welcomed by the market. For the desktop suction type screen printing machine, because there is not enough space to place the compression pump, a simple vacuum device is needed, so the suction power cannot be compared with the vertical screen printing machine. In order to reduce the investment, some users require the production of a larger area of the table, which is not recommended because the stability of the machine will be restricted.