|

|

|

|

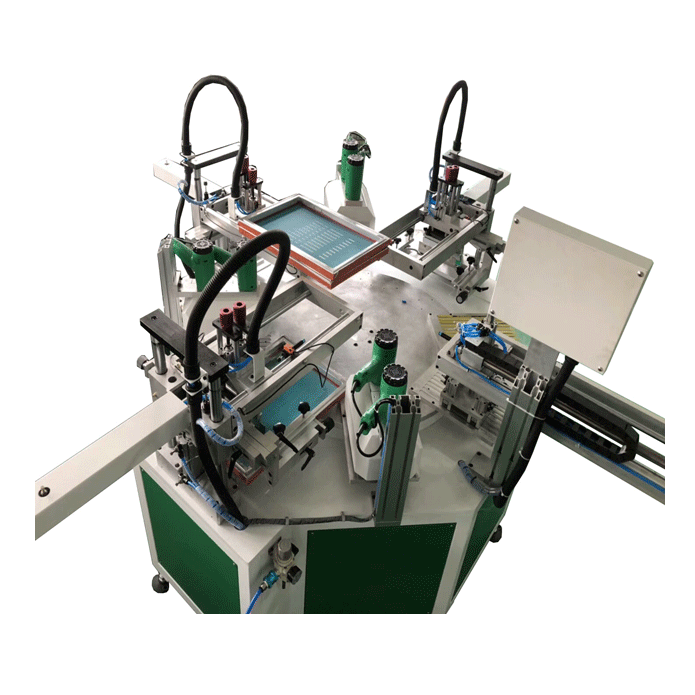

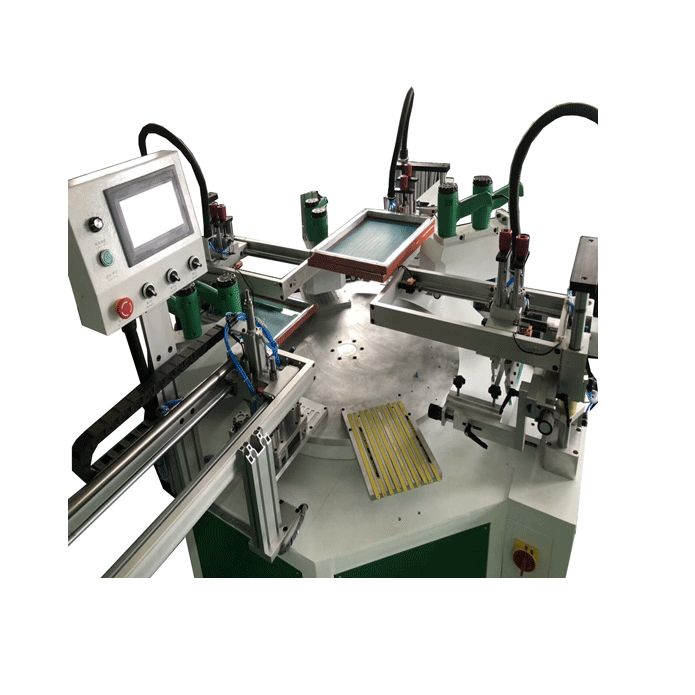

3 colors automatic Flat screen Printer with truntable

Model No.︰

SA3-2030PT8R

Brand Name︰

KC

Country of Origin︰

China

Unit Price︰

US $ 38766 / pic

Minimum Order︰

1 pic

Product Description

The speed of the shuttle multi-color screen printing machine is relatively slow, and it is difficult to meet the needs of users with high output requirements. The multi-color turntable flat screen printing machine is still the best-selling model in the market. The screen printing system and UVLED curing system of the multi-color screen printing machine are arranged around a central axis and remain in a fixed state, while the jig and products are placed on the disc that rotates around the central axis, and the stop position is controlled by the divider. When the turntable stops , the silk screen printing system descends for silk screen printing, and then turns to the next station for UVLED curing.

The turntable screen printing machine can still achieve high-precision overprinting through precise operation, and the printing speed can be increased by 2 times. This is the design scheme of the main screen printing machine and has been widely accepted by the market.

Since the space of the turntable screen printing machine is large enough, the adjustment process is more convenient. The multi-station setting of the workbench can also facilitate the installation of pre-press processing devices, feeding manipulators and unloading manipulators, which further increases the intelligence of printing. .

|

SA3-2030PT8R Automatic 3 colors Flat screen printing machine with rotating table //Structure |

|

|

Working table |

Rotating working table, Size: 200*300mm |

|

Actions |

Up-down of screen plate |

|

To be printed |

|

|

Squeegee stroke |

Adjust the Limited switch |

|

Squeegee and screen plate control |

High precision guide shaft |

|

SA3-2030PT8R Automatic 3 colors Flat screen printer with Rotating table //Usage and characters |

|

|

Guide |

|

|

Application |

|

|

SA3-2030PT8R Flat screen printing Machine with rotating table//Parameters |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package parameters |

|

|

|

|

H.S.CODE |

8443192190 |

|

Certificate |

CE |

|

SA3-2030PT8R 3 Colors Flat screen printing Machine with rotating table //Advantage |

|

|

Function |

|

The turntable screen printing machine can still achieve high-precision overprinting through precise operation, and the printing speed can be increased by 2 times. This is the design scheme of the main screen printing machine and has been widely accepted by the market.

Since the space of the turntable screen printing machine is large enough, the adjustment process is more convenient. The multi-station setting of the workbench can also facilitate the installation of pre-press processing devices, feeding manipulators and unloading manipulators, which further increases the intelligence of printing. .