|

|

|

|

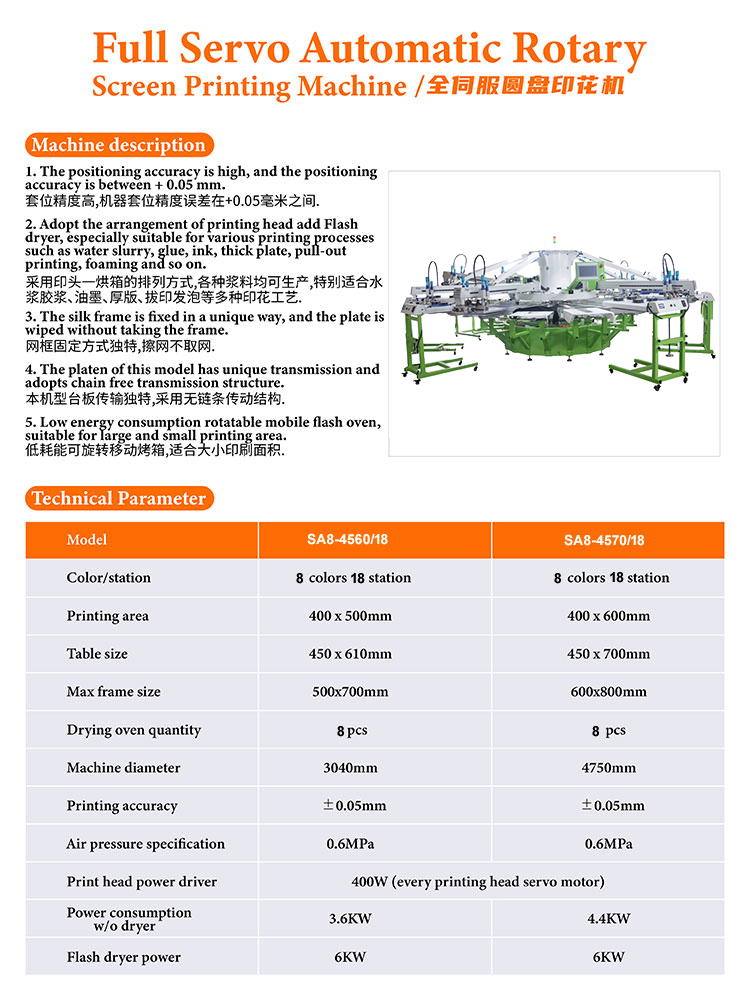

Full automatically 8 colors T shirt screen printing machine

Model No.︰

SA8-4570/18

Brand Name︰

KC

Country of Origin︰

China

Unit Price︰

US $ 27481 / pic

Minimum Order︰

1 pic

Product Description

The automation of garment cutting screen printing machines is also a market trend. In terms of overprinting accuracy and ease of operation, the oval automatic screen printing machine has certain advantages, but it occupies a large area and costs high. For small and medium garment printing factories , The octopus-style multi-color screen printing machine still has a large market space. The multi-color octopus screen printing machine adopts manual loading, that is, the materials and clothing are placed on the workbench by hand. The workbench can have 8-10-12-14 or more according to the number of colors of the machine, and some stations are used for For silk screen printing, some stations are used for drying. In principle, the stations need to be installed with a swing oven to ensure that the surface of the ink is dry and avoid the phenomenon of sticking between colors. The workbench of the screen printing machine can automatically rotate to the next screen printing position to print the next color. In order to improve the accuracy, the screen printing machine adopts a certain mechanical positioning device. At the same time, the upper and lower sides of the screen are controlled by servo motors.

The automatic rotary cutting screen printing machine is another representative of the forward and backward movement of the scraper in the type of screen printing machine. We know that the oblique arm screen printing machine is such a structure, which makes it easier to place and remove products. If you are tired of the hard work of manual screen printing machines and do not plan to buy oval screen printing machines, then you can consider disc screen printing machines.

|

SA8-4570/18 Automatically 8-color garment screen printing machine//Structure |

||

|

Location |

Sensor |

|

|

Working table |

High strength cast aluminum plate -450*650mm |

|

|

Actions |

automatically Rotating screen plate |

|

|

To be printed |

|

|

|

Rotating angle |

45 |

|

|

Squeegee and screen plate control |

High precision rotating disc |

|

|

Ink drying |

Heat set ink, IR Drying |

|

|

SA8-4570/18 automatically 8-color Garment screen printing machine//Usage and characters |

||

|

Guide |

|

|

|

Application |

|

|

|

SA8-4570/18 Automatically 8-color garment screen printing Machine //Parameters |

||

|

Technical parameters |

SA8-4570/18 8-colour automatically rotating flat screen printing machine

|

|

|

Works supply |

|

|

|

Package parameters |

|

|

|

H.S.CODE |

8443198000 |

|

|

Certificate |

CE |

|

|

SA8-4570/18 Automatically 8-color garment screen printing machine//Advantage |

||

|

Function |

|

|

The automatic rotary cutting screen printing machine is another representative of the forward and backward movement of the scraper in the type of screen printing machine. We know that the oblique arm screen printing machine is such a structure, which makes it easier to place and remove products. If you are tired of the hard work of manual screen printing machines and do not plan to buy oval screen printing machines, then you can consider disc screen printing machines.