|

|

|

|

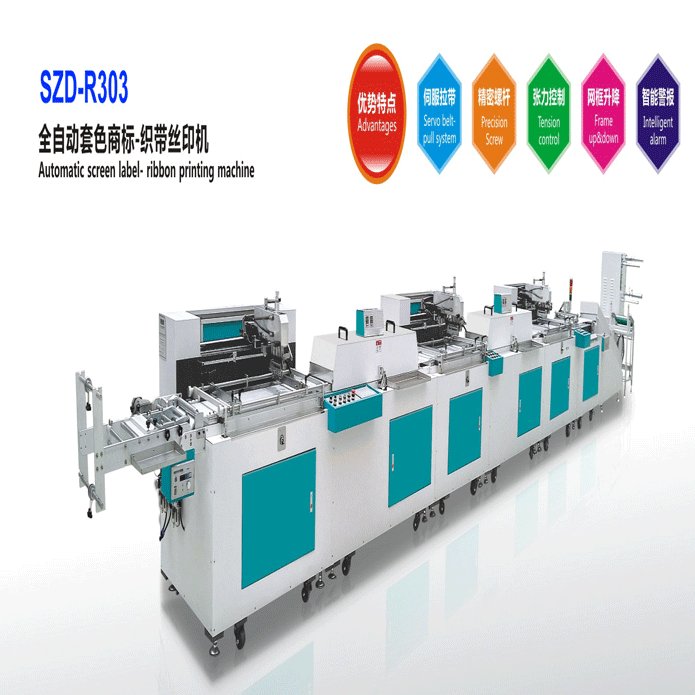

Automatically ribbon Three colors screen printing machine

Model No.︰

SZD-303RA

Brand Name︰

KC

Country of Origin︰

China

Unit Price︰

US $ 35626 / pic

Minimum Order︰

1 pic

Product Description

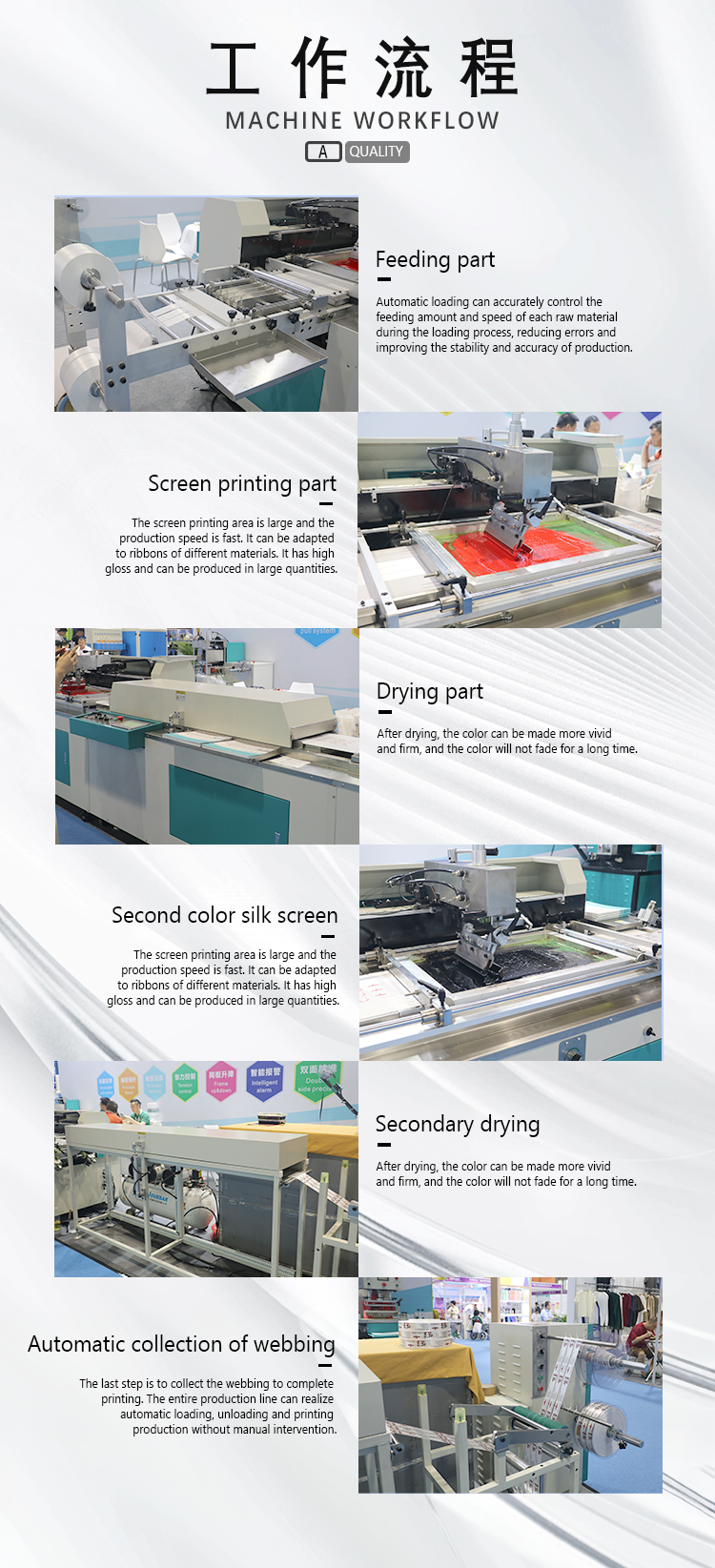

The screen printing machine for printing continuous strips and roll materials belongs to the category of roll-to-roll screen printing machines. There are two main types. One is the screen printing machine for printing paper, film and other materials with good dimensional stability. It has the following characteristics:

1) The workbench adopts an aluminum alloy suction screen printing table. When the roll material is transported to the printing position according to a certain distance, the material stops moving, the suction action opens, and the printing is completed. Then, the roll material continues to be pulled forward.

2) The drying of the machine can use a winding drying furnace, which saves the space occupied by the machine under the condition of ensuring the drying of the material. Now there are also some product packages that use UV drying or UVLED drying. A curing unit can be installed in the post-printing process, and the UV ink is dried instantly, so the footprint of the machine is greatly reduced.

3) The photoelectric tracking switch is installed at the front of the machine table, and the single-color screen printing machine can perform overprinting of the second color. The machine can connect multiple monochrome machines to complete multi-color overprinting.

This roll-to-roll screen printing machine is suitable for printing paper packaging, membrane switches, thermal transfer films and other products. With the development of the market, the functions of roll-to-roll machines have been greatly improved. For example, adding a thermal transfer unit can realize cold stamping. When printing thermal transfer film, the machine can be equipped with an automatic powder shaker unit, and some factories will Add die-cutting or cutting function.

There is also a kind of screen printing machine with stretchability and elasticity such as printing ribbons. Its characteristics are as follows:

1) The workbench adopts a synchronous belt driven by a motor, and the product will move forward with the synchronous belt for a certain distance for printing, which avoids the graphic deformation caused by the expansion and contraction deformation of the product during printing.

2) Ribbon and other products are basically printed with thermosetting ink and glue, and the ink drying adopts IR drying process, and the length of the drying oven varies from 2 meters to 4 meters. Currently, webbing products rarely use UV curing process.

|

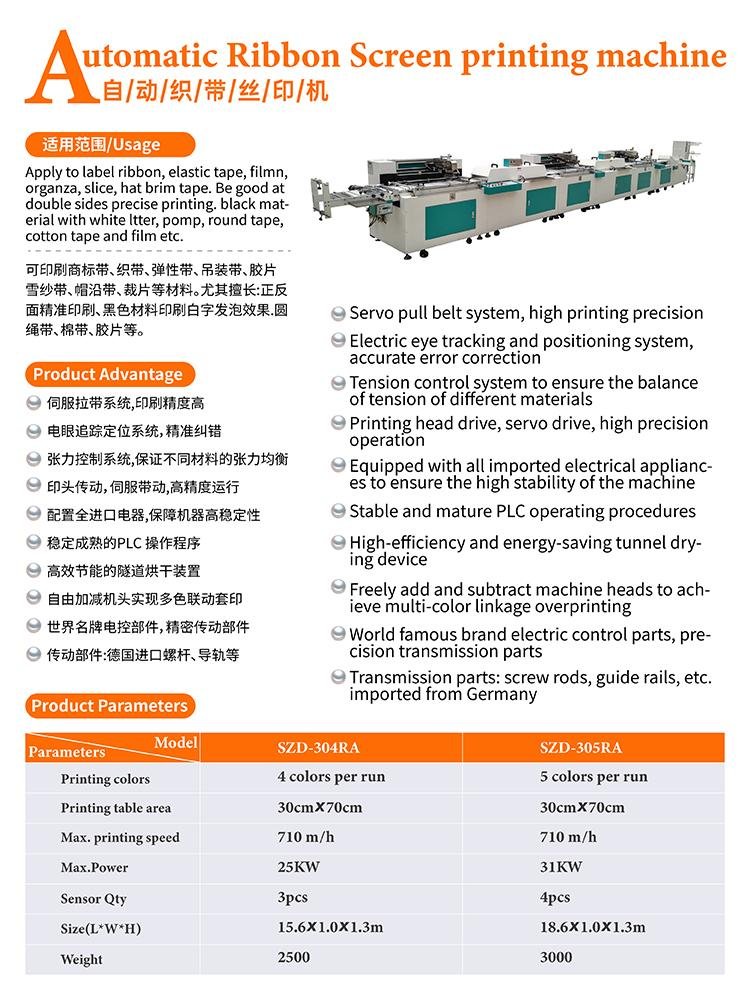

SZD-303RA Full automatically Ribbon screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application fields |

|

|

SZD-303RA Full automatically Ribbon screen printing machine//Parameter |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certificate |

CE |

|

SZD-303RA Full automatically Ribbon screen printing machine//Advantage |

|

|

Function |

|

Product Image

ribbon screen printing machine

ribbon screen printing machine

ribbon screen printing machine

ribbon screen printing machine

ribbon screen printing machine

ribbon screen printing machine

ribbon screen printing machine

ribbon screen printing machine

ribbon screen printing machine

ribbon screen printing machine

ribbon screen printing machine

ribbon screen printing machine